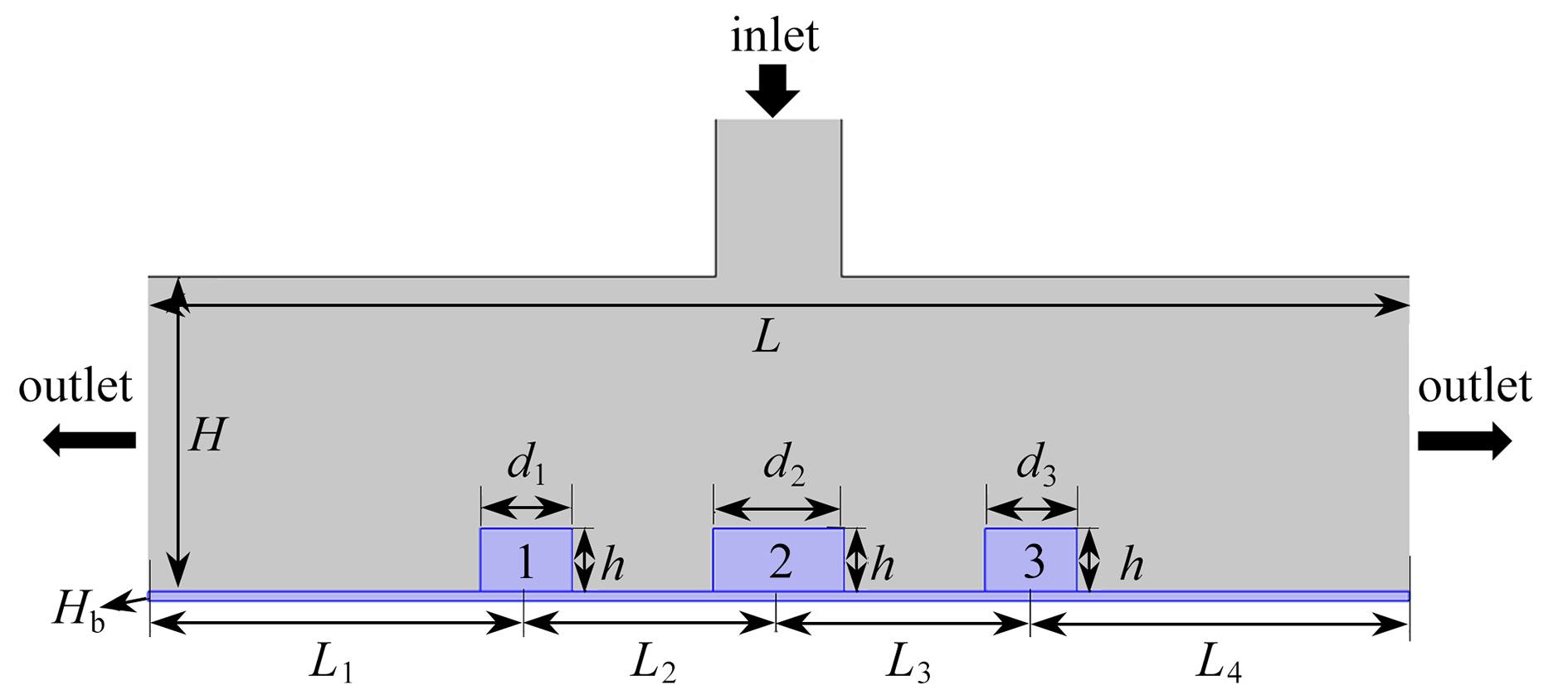

Geometry Design of Square Column Heating Devices in Jet Channels

-

摘要:

基于构形理论,建立了二维射流通道内导热基座上方柱离散热源的散热优化模型。给定离散热源的总纵截面面积和热源高度为约束条件,以系统最高温度和熵产率为优化目标,以各热源的长度比为优化变量进行了几何设计,并分析了射流速度和热源间距对热源最优构形的影响。当射流速度和热源间距给定时,均存在最优长度比使系统最高温度和熵产率最低,但对应不同射流速度和热源间距的最优长度比不同。研究结果可为方柱发热器件的热设计提供理论指导。

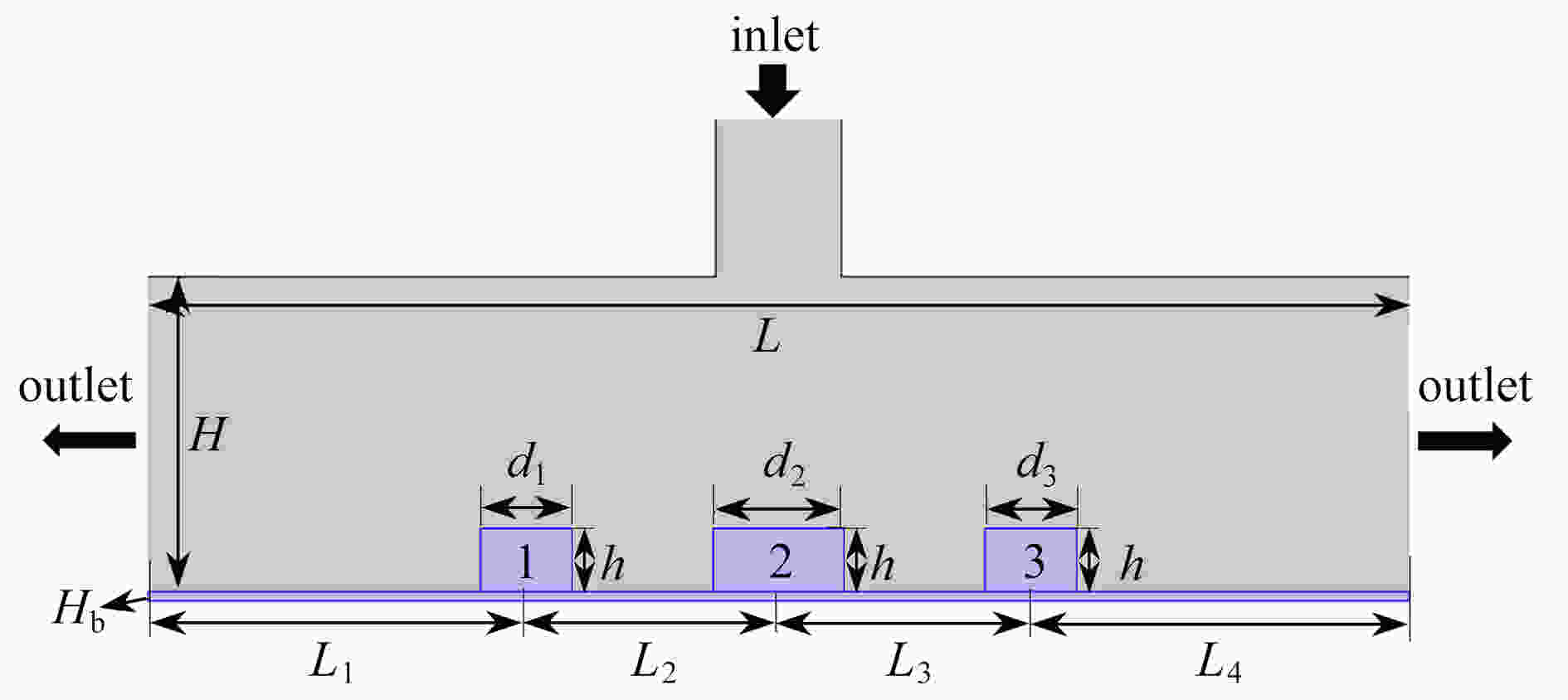

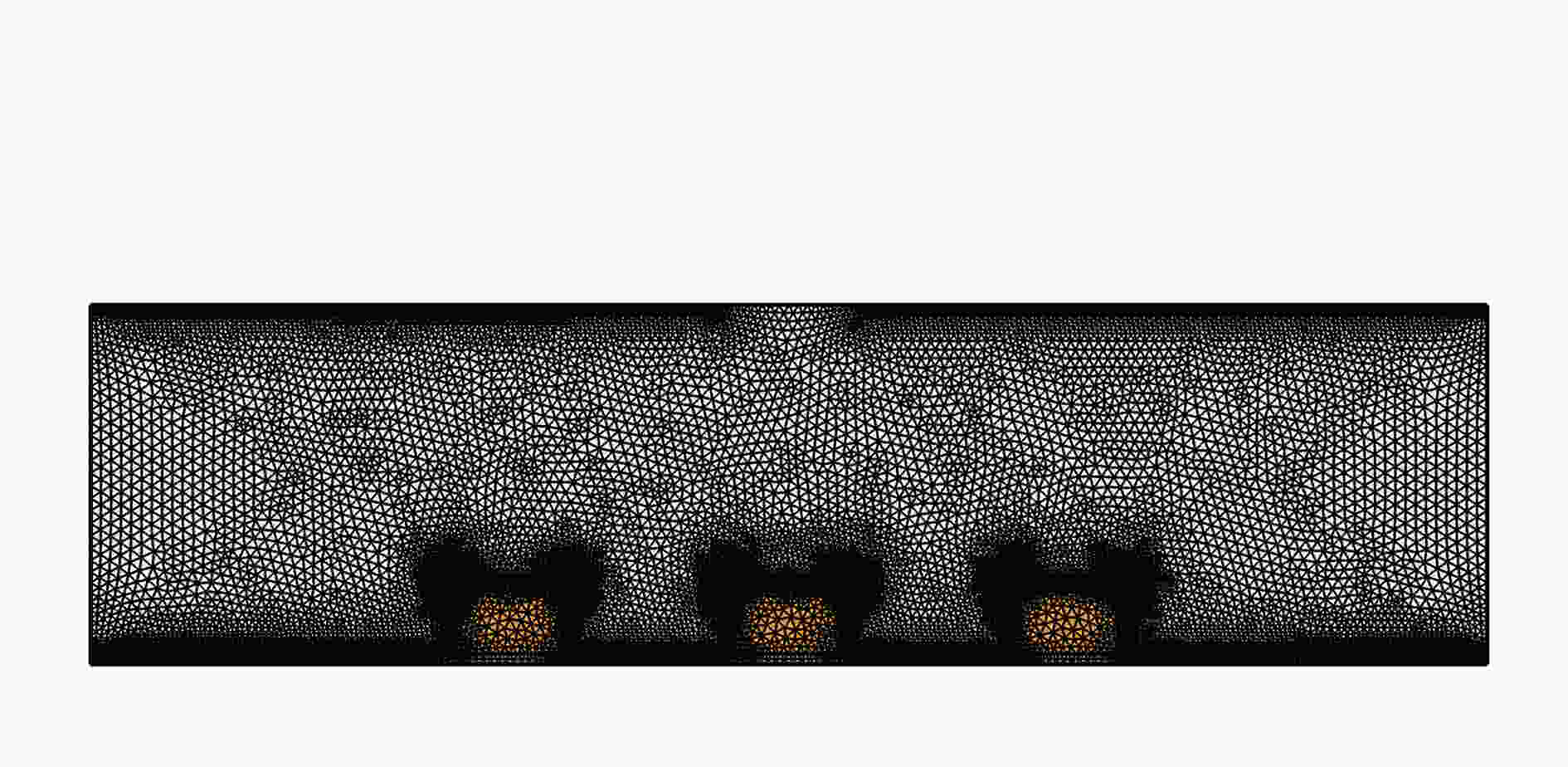

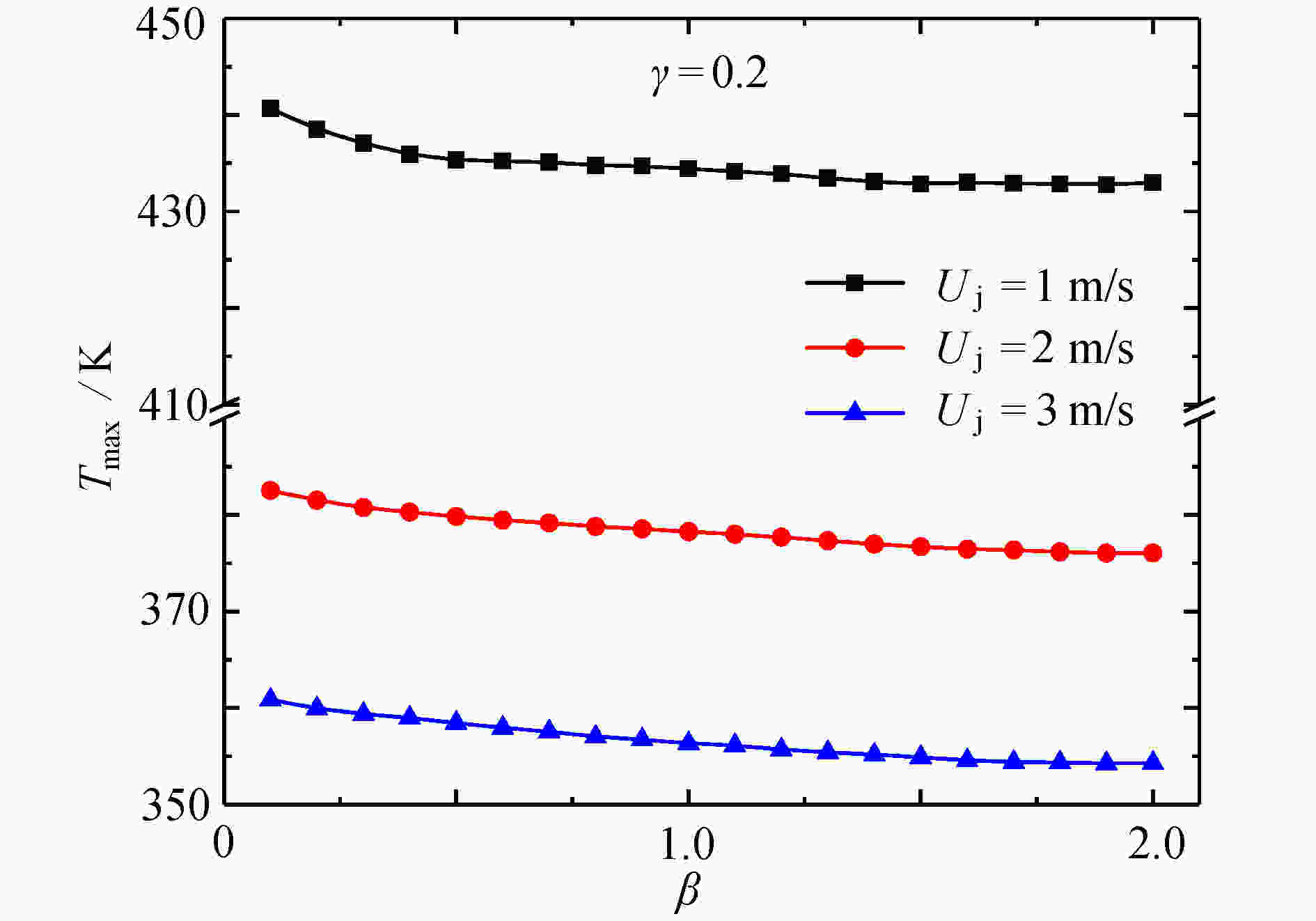

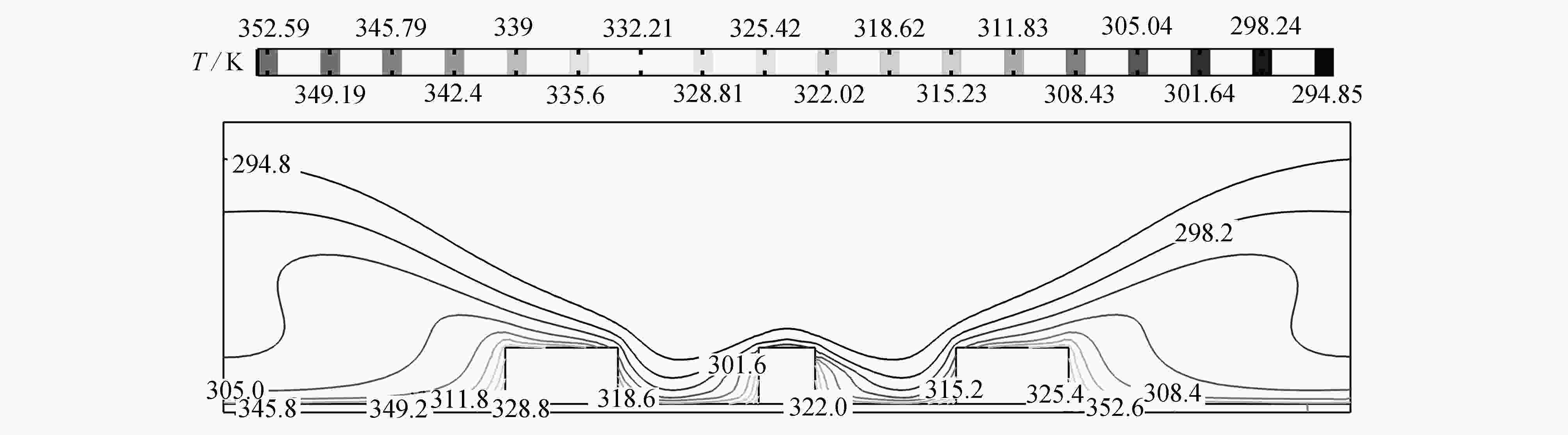

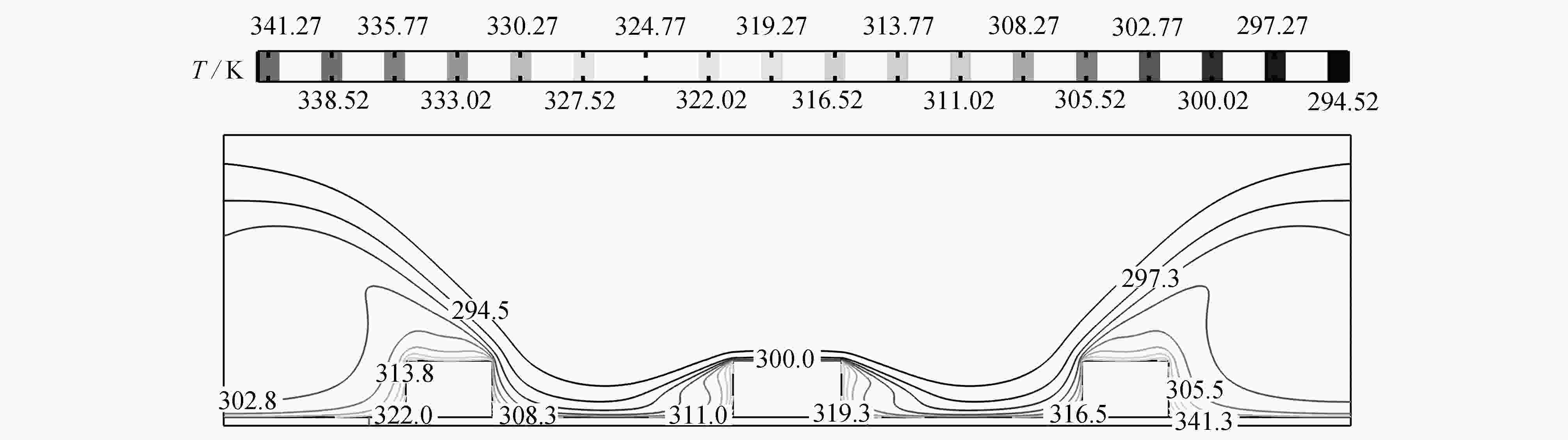

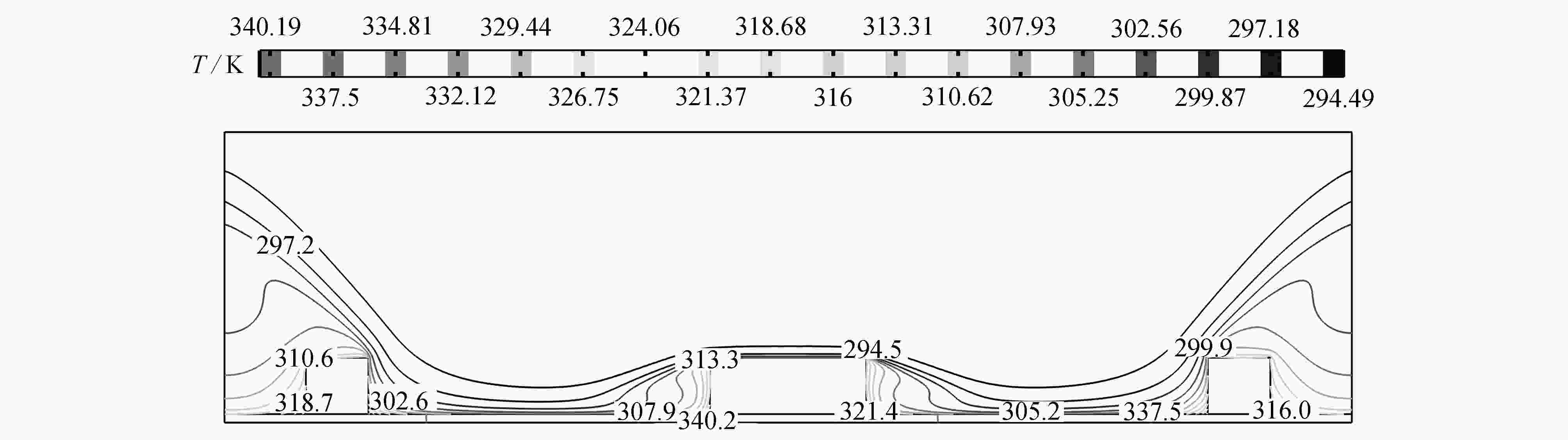

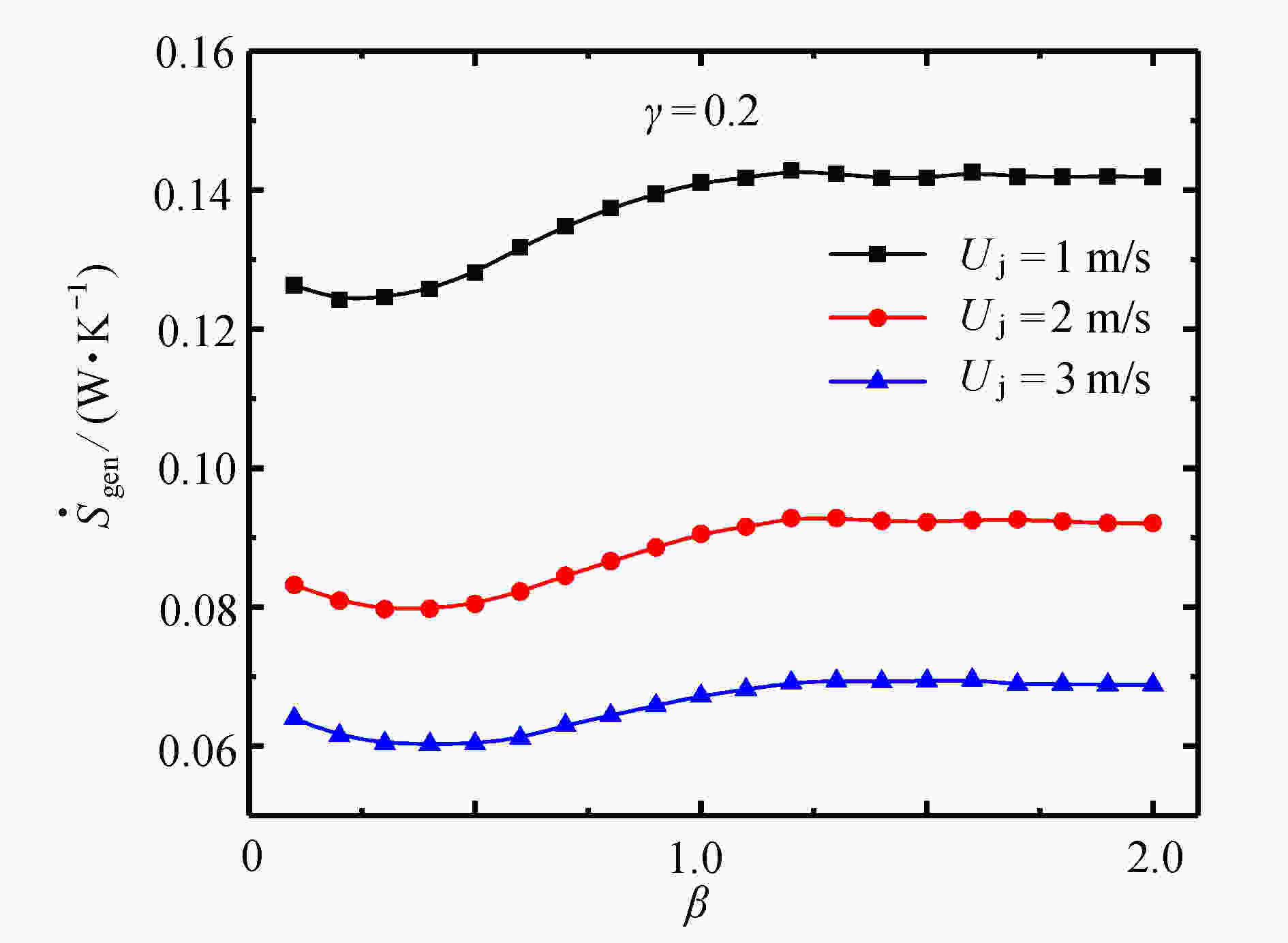

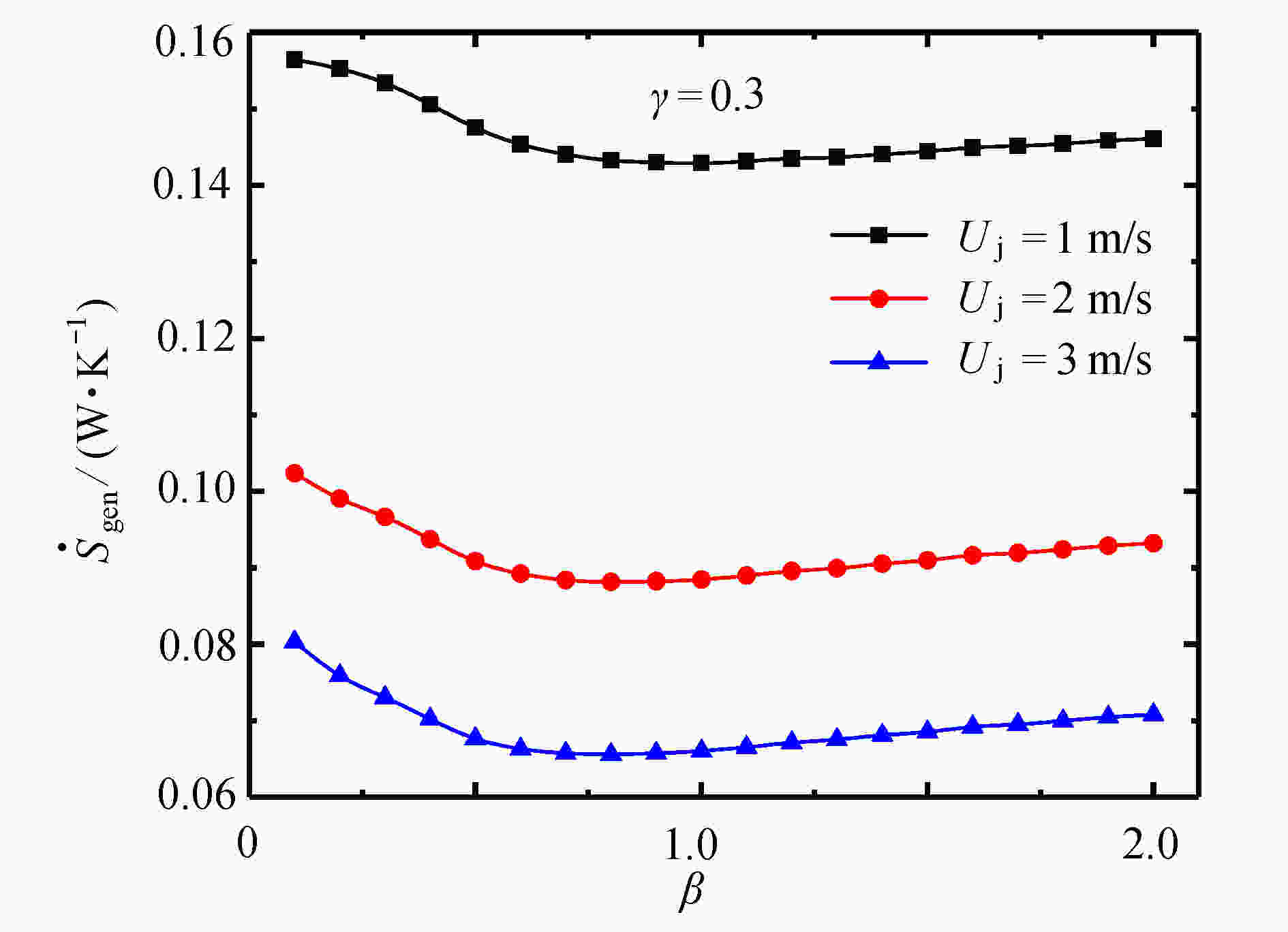

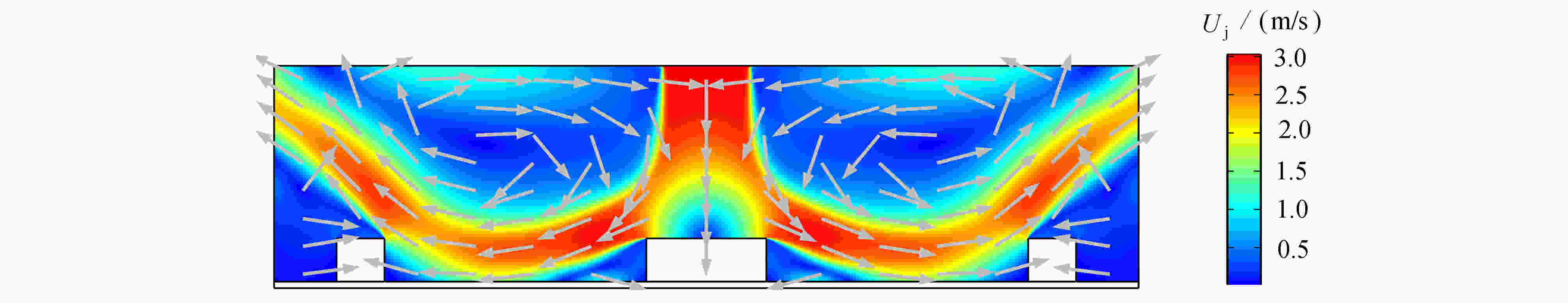

Abstract:Based on the constructal theory, a heat dissipation optimization model for discrete square column heating devices on thermal conduction bases in 2D jet channels was established. With the total longitudinal section area and the discrete heat source height as constraints, the maximum temperature and entropy production rate of the system were taken as optimization objectives, and the length ratio of each heating device was taken as the optimization variables in the geometry design. The effects of the jet velocity and the heating device spacing on the constructal optimization of the heating device were analyzed. When the jet velocity and the heating device spacing are fixed, there will exist optimal length ratios to minimize the maximum temperature and the entropy production rate of the system, but the optimal length ratios corresponding to different jet velocities and different heating devices spacings are different. The results provide a theoretical guidance for the thermal design of square column heating devices.

-

表 1 网格独立性检验

Table 1. The grid independence test

order number number of units N Tmax/K $| {( {T_{ {\rm{\max} } }^{j + 1} - T_{ {\rm{\max} } }^j} )/T_{ {\rm{\max } } }^j} |/\text{%}$ 1 29 085 432.67 – 2 69 132 434.12 0.34 3 108 055 434.97 0.2 表 2 模型有效性验证

Table 2. Validation of the model

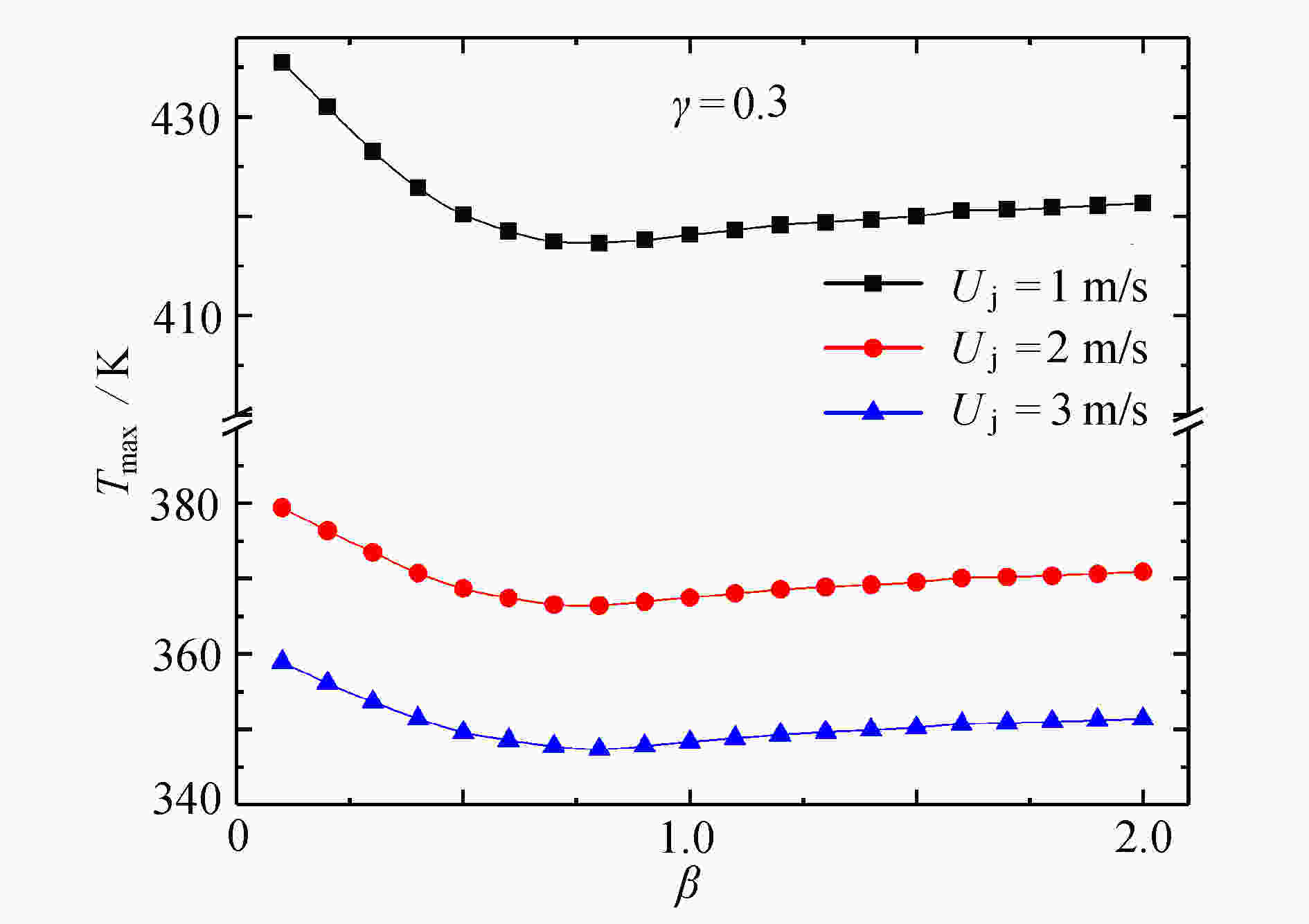

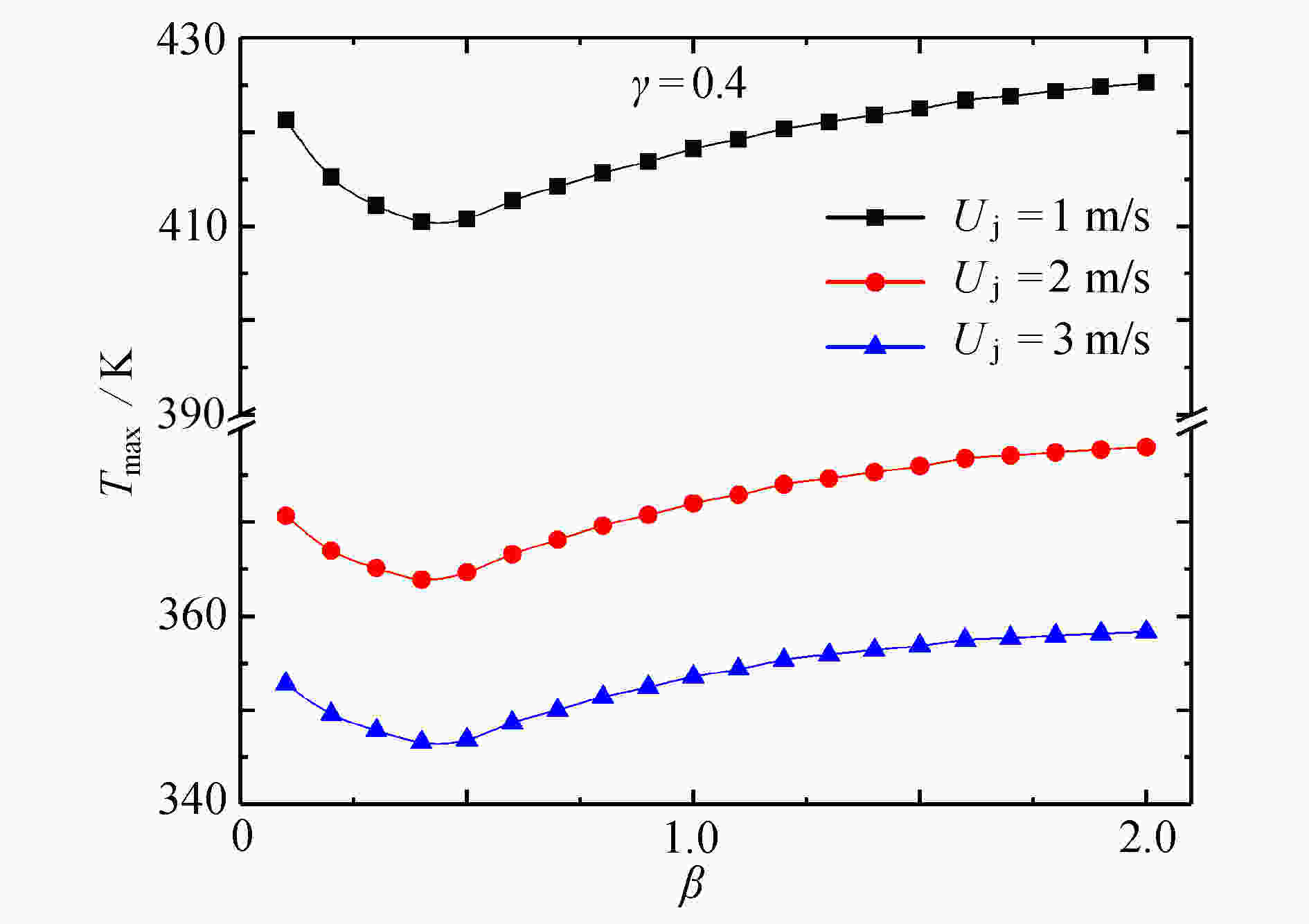

$\tilde H$ 0.1 0.2 b 0.465 2 0.483 5 $\tilde T$[22] 7.233 9 13.650 9 $\tilde T$ 7.191 5 13.534 3 表 3 不同Uj时,Tmax,min及对应的几何参数

Table 3. Tmax,min and its corresponding geometric parameters for different Uj values

Uj/(m·s−1) γ βopt Tmax,min/K 1 0.2 2 433 1 0.3 0.8 417.5 1 0.4 0.4 410.5 2 0.2 2 376 2 0.3 0.8 362.8 2 0.4 0.4 360.2 3 0.2 2 354.3 3 0.3 0.8 342.6 3 0.4 0.4 341.5 表 4 不同Uj时,

${\dot S_{ {\rm{gen}},\min }}$ 及对应的几何参数Table 4.

${\dot S_{ {\rm{gen}},\min }}$ and its corresponding geometric parameters for different Uj valuesUj/(m·s−1) γ βopt ${\dot S_{ {\rm{gen,\min } } } }/({\rm{W \cdot K} }^{-1})$ 1 0.2 0.4 0.12575 1 0.3 0.9 0.14298 1 0.4 0.4 0.13021 2 0.2 0.3 0.07972 2 0.3 0.8 0.088153 2 0.4 0.3 0.083012 3 0.2 0.4 0.060294 3 0.3 0.8 0.06559 3 0.4 0.4 0.07022 -

[1] ERP R V, SOLEIMANZADEH R, NELA L, et al. Co-designing electronics with microfluidics for more sustainable cooling[J]. Nature, 2020, 585(7824): 211-216. doi: 10.1038/s41586-020-2666-1 [2] RAVANJI A, ZARGARABADI M R. Effects of pin-fin shape on cooling performance of a circular jet impinging on a flat surface[J]. International Journal of Thermal Sciences, 2021, 161: 106684. doi: 10.1016/j.ijthermalsci.2020.106684 [3] LIU J, HUSSAIN S, WANG W, et al. Experimental and numerical investigations of heat transfer and fluid flow in a rectangular channel with perforated ribs[J]. International Communications in Heat and Mass Transfer, 2021, 121: 105083. doi: 10.1016/j.icheatmasstransfer.2020.105083 [4] JIN W, WU J M, JIA N, et al. Effect of shape and distribution of pin-fins on the flow and heat transfer characteristics in the rectangular cooling channel[J]. International Journal of Thermal Sciences, 2021, 161: 106758. doi: 10.1016/j.ijthermalsci.2020.106758 [5] 许丽娜, 菅永军. 柔性圆柱形微管道内的电动流动及传热研究[J]. 应用数学和力学, 2019, 40(4): 408-418XU Lina, JIAN Yongjun. Electrokinetic flow and heat transfer in soft microtubes[J]. Applied Mathematics and Mechanics, 2019, 40(4): 408-418.(in Chinese) [6] 李迎雪, 王浩原, 娄钦. 含多个矩形加热器通道内流动沸腾传热性能的介观数值方法研究[J]. 应用数学和力学, 2022, 43(7): 728-740LI Yingxue, WANG Haoyuan, LOU Qin. Mesoscopic numerical study on flow boiling heat transfer performance in channels with multiple rectangular heaters[J]. Applied Mathematics and Mechanics, 2022, 43(7): 728-740.(in Chinese) [7] RUNDSTROEM D, MOSHFEGH B. Investigation of heat transfer and pressure drop of an impinging jet in a cross-flow for cooling of a heated cube[J]. Journal of Heat Transfer, 2008, 130(12): 320-327. [8] MEGHDIR A, BENABDALLAH T, DELLIL A. Impact of geometry of electronic components on cooling improvement[J]. International Journal of Heat and Technology, 2019, 37(1): 167-178. doi: 10.18280/ijht.370121 [9] BEJAN A. Entropy Generation Through Heat and Fluid Flow[M]. New York: Wiley, 1982. [10] BEJAN A. Entropy Generation Minimization[M]. New York: Wiley, 1996. [11] REHMAN M M U, CHEEMA T A, AHMAD F, et al. Thermodynamic assessment of microchannel heat sinks with novel sidewall ribs[J]. Journal of Thermophysics and Heat Transfer, 2020, 34(2): 243-254. doi: 10.2514/1.T5770 [12] PATI S, ROY R, DEKA N, et al. Optimal heating strategy for minimization of peak temperature and entropy generation for forced convective flow through a circular pipe[J]. International Journal of Heat and Mass Transfer, 2020, 150: 119318. doi: 10.1016/j.ijheatmasstransfer.2020.119318 [13] KINGSTON D, WILHELMSEN Ø, KJELSTRUP S. Minimum entropy production in a distillation column for air separation described by a continuous non-equilibrium model[J]. Chemical Engineering Science, 2020, 218: 115539. doi: 10.1016/j.ces.2020.115539 [14] BEJAN A. Street network theory of organization in nature[J]. Journal of Advanced Transportation, 1996, 30(2): 85-107. doi: 10.1002/atr.5670300207 [15] BEJAN A, LORENTE S. Design With Constructal Theory[M]. New Jersey: Wiley, 2008. [16] CHEN L G. Progress in study on constructal theory and its applications[J]. Science China: Technological Sciences, 2012, 55(1): 802-820. [17] CHEN L G, FENG H J, XIE Z H, et al. Progress of constructal theory in China over the past decade[J]. International Journal of Heat and Mass Transfer, 2019, 130: 393-419. doi: 10.1016/j.ijheatmasstransfer.2018.10.064 [18] CHEN L G, WU W J, FENG H J. Consturctal Design for Heat Conduction[M]. London: Book Publisher International, 2021. [19] WANG L, XIE Z H, CHEN L G, et al. Equivalent thermal resistance minimization for a circular disc heat sink with reverting microchannels based on constructal theory and entransy theory[J]. Science China: Technological Sciences, 2021, 64(1): 111-121. doi: 10.1007/s11431-020-1578-6 [20] MUSTAFA A W, GHANI I A. Maximization of heat transfer density from a vertical array of flat tubes in cross flow under fixed pressure drop using constructal design[J]. Heat Transfer: Asian Research, 2019, 48(8): 3489-3507. doi: 10.1002/htj.21551 [21] ABBAS N Y, MUSTAFA A W, ASKER M K A A. Constructal design of longitudinally finned tubes cooled by forced convection[J]. Heat Transfer, 2020, 49(3): 5-9. [22] AHMED W M, HAJIR H A E. Constructal design of multiscale elliptic tubes in crossflow[J]. Heat Transfer, 2020, 49(4): 12-16. [23] YU M J, FENG X, LAI X T, et al. Study of oscillating flows through a novel constructal bifurcation Stirling regenerator[J]. Applied Thermal Engineering, 2021, 184: 116413. doi: 10.1016/j.applthermaleng.2020.116413 [24] GONG S W, CHEN L G, FENG H J, et al. Constructal optimization of cylindrical heat sources surrounded with a fin based on minimization of hot spot temperature[J]. International Communications in Heat and Mass Transfer, 2015, 68: 1-7. doi: 10.1016/j.icheatmasstransfer.2015.08.004 [25] 范旭东, 谢志辉, 孙丰瑞, 等. 变物性条件下基于(火 积)理论的圆柱体热源构形研究[J]. 工程热物理学报, 2016, 37(9): 1994-1999FAN Xudong, XIE Zhihui, SUN Fengrui, et al. Constructal investigation of a cylindrical heat source based on entransy theory with temperature-dependent properties[J]. Journal of Engineering Thermophysics, 2016, 37(9): 1994-1999.(in Chinese) [26] 王刚, 谢志辉, 范旭东, 等. 离散发热器件基于(火 积)耗散率最小和最高温度最小的构形优化比较[J]. 物理学报, 2017, 66(20): 130-138 doi: 10.7498/aps.66.204401WANG Gang, XIE Zhihui, FAN Xudong, et al. Constructal optimization of discrete heating devices based on entransy dissipation rate and maximum temperature minimization[J]. Acta Physica Sinica, 2017, 66(20): 130-138.(in Chinese) doi: 10.7498/aps.66.204401 [27] TEIXEIRA F B, LORENZINI G, ERRERA M R, et al. Constructal design of triangular arrangements of square bluff bodies under forced convective turbulent flows[J]. International Journal of Heat and Mass Transfer, 2018, 126(A): 521-535. [28] AGHENESE A P D, TEIXEIRA F B, ROCHA L A O. Geometric evaluation of four staggered cylinders array subjected to forced convective flows by means of constructal design[J]. Thermal Engineering, 2019, 18(1): 57-63. [29] RAZERA A L, QUEZADA L A, FAGUNDES T M. Fluid flow and heat transfer maximization of elliptic cross-section tubes exposed to forced convection: a numerical approach motivated by Bejan’s theory[J]. International Communications in Heat and Mass Transfer, 2019, 109: 104366. doi: 10.1016/j.icheatmasstransfer.2019.104366 [30] WANG R, XIE Z H, YIN Y, et al. Constructal design of elliptical cylinders with heat generating for entropy generation minimization[J]. Entropy, 2020, 22(6): 651. doi: 10.3390/e22060651 -

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号