Optimization Design of Holding Poles Based on the Response Surface Methodology and the Improved Arithmetic Optimization Algorithm

-

摘要:

抱杆优化设计需要耗费大量有限元分析计算时间,难以确定可行域。该文采用响应面法(response surface method,RSM)来模拟抱杆结构的真实响应,提出了改进的算术优化算法(improved arithmetic optimization algorithm,IAOA)对抱杆结构进行优化设计。将分数阶积分引入算术优化算法(arithmetic optimization algorithm,AOA),改善了算法的开发能力。采用拉丁超立方抽样,选取抱杆结构杆件截面试验样本,利用最小二乘法对样本点进行分析,构建了抱杆结构应力和位移关于杆件截面尺寸的二阶响应面代理模型。建立以抱杆质量最小化为优化目标,许用应力和位移为约束条件的优化模型,采用IAOA对其进行求解。结果表明:二阶响应面模型能够准确预测抱杆结构的响应值,IAOA的求解精度得到显著提升,代理模型可大幅降低有限元分析所需的计算代价,优化后抱杆结构质量减轻了8.2%。联合使用RSM和IAOA可有效求解大型空间杆系结构的优化设计问题。

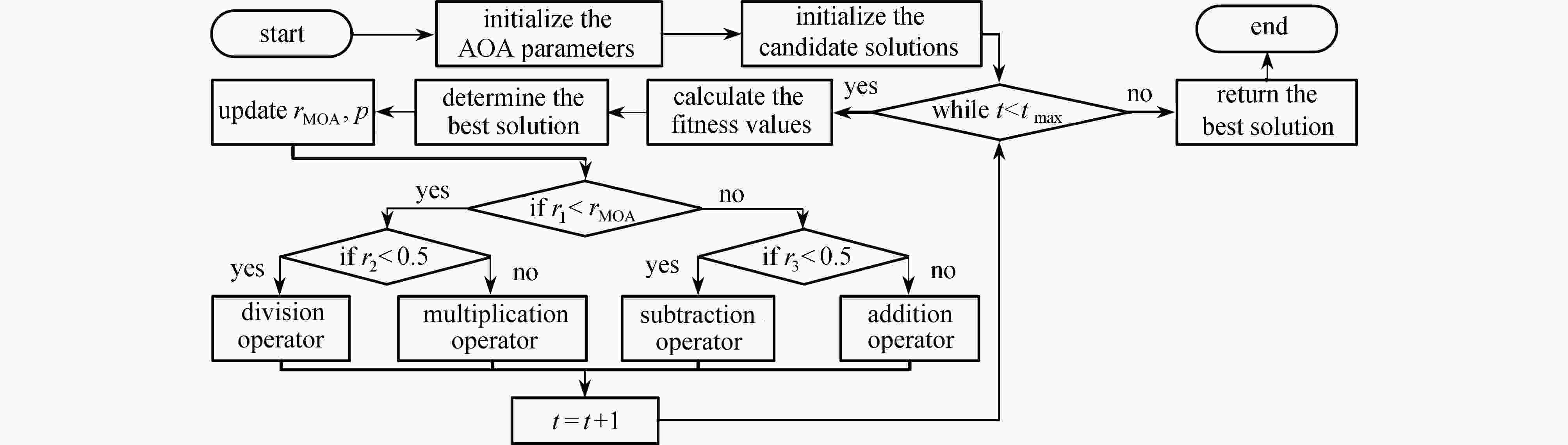

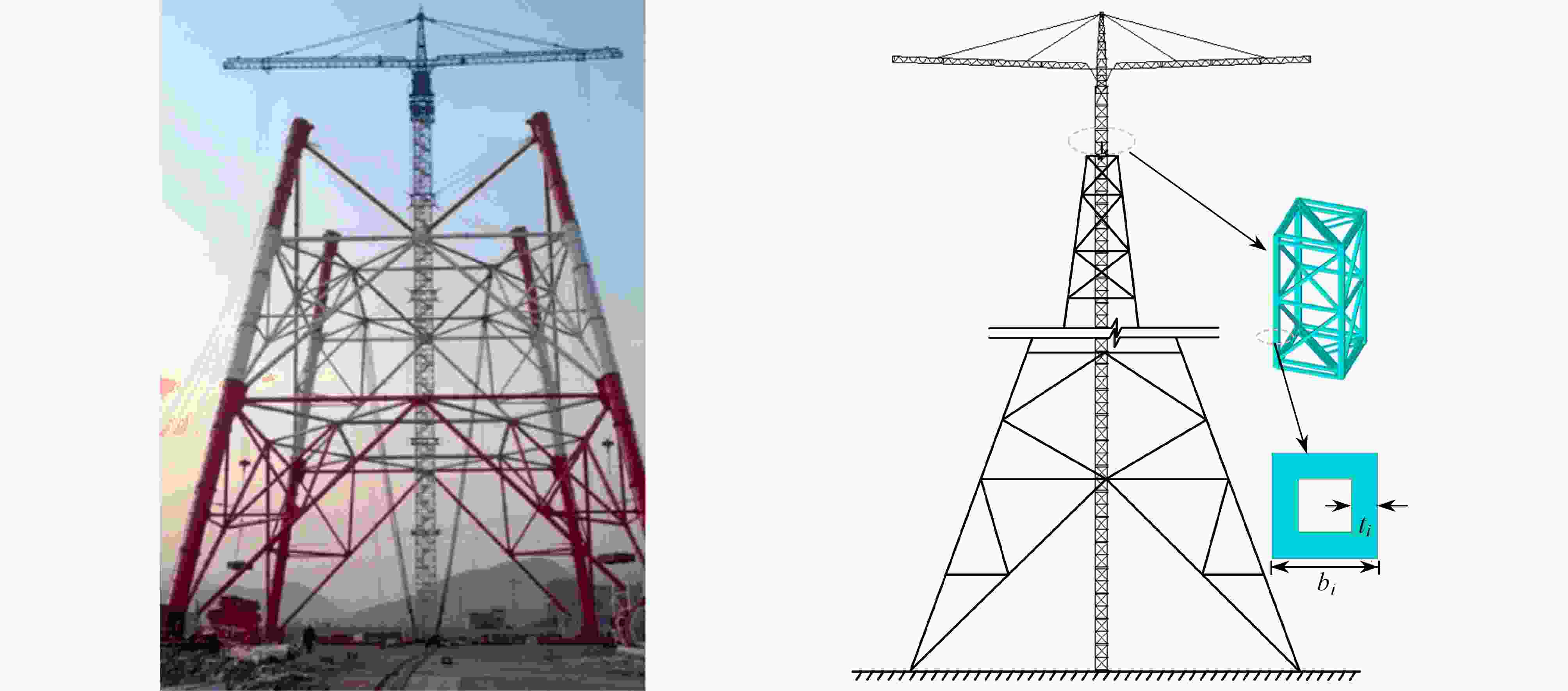

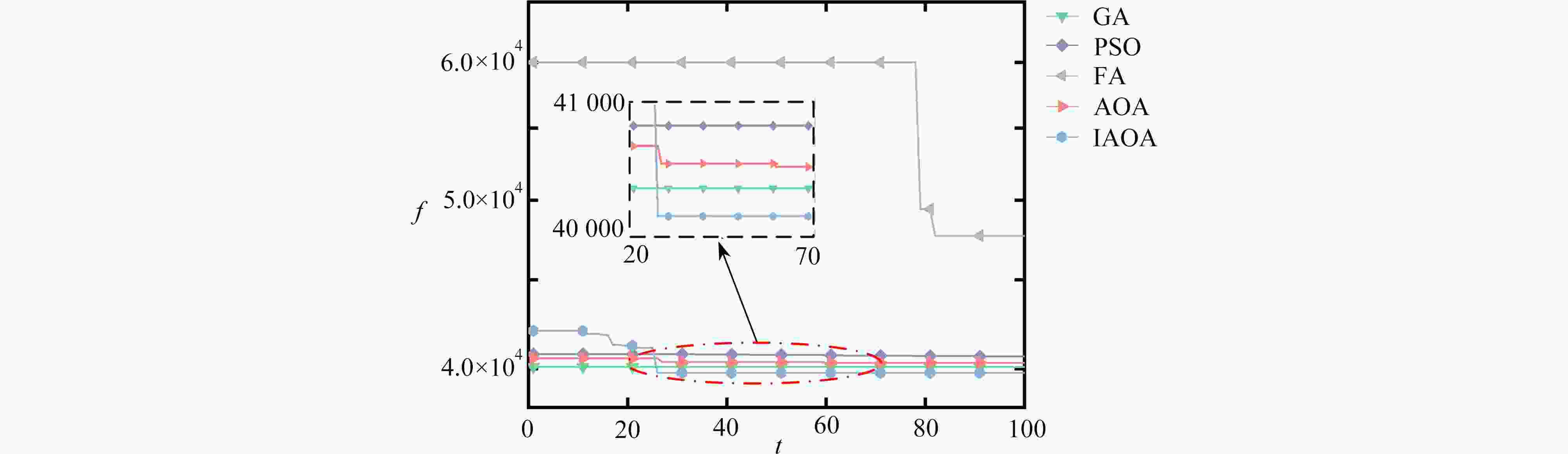

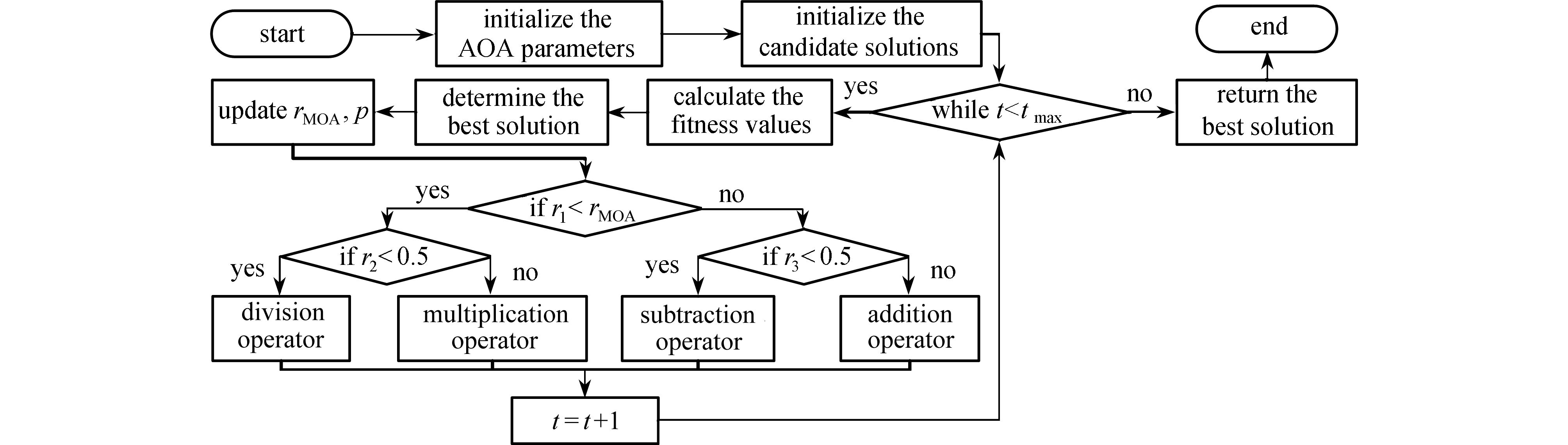

Abstract:The computation consumption of finite element analysis for structural optimization design of holding poles is large, and it is difficult to determine the feasible region. The response surface method (RSM) was used to simulate the real response of the holding pole, and an improved arithmetic optimization algorithm (IAOA) was proposed to optimize the holding pole. The fractional-order calculus was introduced into the arithmetic optimization algorithm (AOA) to improve the exploitation ability of the AOA. The Latin hypercube sampling was applied to select the test samples of each member of the holding pole, and the least square method was employed to analyze the sample points. Then, the 2nd-order response surface surrogate model for the stress and displacement of the holding pole on the cross-sectional sizes of each member was established. An optimization model was constructed with the minimum mass as the optimization objective and the allowable stress and displacement as constraints, and the IAOA was implemented to solve the model. The results show that, the 2nd-order response surface model can accurately predict the response value of the holding pole. The solution accuracy of the IAOA is significantly improved. The surrogate model can greatly decrease the calculation cost of the finite element analysis. The mass of the holding pole is reduced by 8.2% after optimization. The RSM and the IAOA can be combined to solve the optimization design problem of large spatial truss structures effectively.

-

表 1 抱杆结构拉丁超立方试验设计结果

Table 1. Latin hypercube experimental design results of the holding pole

number b1/mm t1/mm b2/mm t2/mm b3/mm t3/mm σ/MPa d/mm 1 112 10 41 3 81 7 112.776 618.502 2 96 8 46 8 73 6 144.207 855.603 3 145 7 87 7 76 4 112.785 640.648 4 147 8 56 4 96 7 112.759 589.670 5 131 11 94 4 44 8 112.745 503.594 6 91 8 85 4 49 5 154.753 879.046 7 143 10 86 6 58 4 112.738 496.787 8 90 8 77 8 81 7 157.628 931.646 9 127 9 65 6 87 7 112.765 618.600 10 109 8 93 6 56 5 120.008 741.433 11 104 10 49 9 60 8 112.789 672.708 12 115 6 47 6 84 8 158.176 925.155 13 140 12 55 8 67 4 112.725 455.399 14 110 9 51 3 60 5 112.800 672.017 15 137 9 92 4 79 5 112.755 563.238 16 128 10 63 5 85 8 112.750 571.317 17 94 8 84 7 80 4 147.380 865.021 18 141 12 64 6 86 8 112.726 472.743 19 121 9 52 4 87 5 112.793 623.275 20 123 12 72 6 54 4 112.746 498.627 21 120 7 76 8 99 7 123.901 800.895 22 106 7 54 7 88 9 147.233 893.174 23 97 11 56 4 94 6 112.787 667.220 24 100 7 76 4 68 5 158.786 903.924 25 147 11 45 4 89 6 112.729 467.172 26 119 10 50 6 50 9 112.764 590.889 27 129 11 69 5 49 3 112.746 507.854 28 105 7 88 4 95 9 148.844 902.907 29 144 11 98 5 91 5 112.723 480.494 30 127 10 87 5 52 8 112.753 558.483 表 2 响应面模型随机样本点检验结果

Table 2. Test results of random sample points for the response surface model

item δ2 δRAAE δRMAE σ/MPa 0.9257 0.0115 0.0635 d/mm 0.9774 0.0195 0.0174 high adaptative interval H 0.9 ~ 1 0 ~ 0.2 0 ~ 0.3 表 3 响应面模型随机非样本点检验结果

Table 3. Test results of random non-sample points for the response surface model

number σ/MPa $ \hat \sigma $/MPa stress error εσ/% d/mm $ \hat d $/mm displacement error εd/% 1 112.7705 111.0160 1.56 576.5725 585.7213 1.59 2 112.7441 115.6223 2.55 515.2002 535.5826 3.96 表 4 各算法的参数值

Table 4. Parameter values for each algorithm

algorithm parameter value GA type real coded selection roulette wheel (proportionate) crossover whole arithmetic (probability = 0.8, α = [−0.5, 1.5]) mutation Gaussian (probability = 0.05) PSO cognitive and social constant inertia weight (C1, C2): (2, 2) linear reduction from 0.9 to 0.1 FA α 0.5 β 0.2 γ 1 AOA α 5 µ 0.5 IAOA α 5 µ 0.5 表 5 不同算法抱杆优化结果对比

Table 5. Optimization results comparison by different algorithms for the holding pole

algorithm b1/mm t1/mm b2/mm t2/mm b3/mm t3/mm W/kg evaluation number GA 146 11 40 10 40 10 40 721.26 1 000 PSO 150 12 40 10 40 5 40 773.77 1 000 FA 144 11 59 9 85 8 47 689.62 1 000 AOA 150 12 40 10 40 4 40 164.25 1 000 IAOA 150 10 40 10 40 10 39 780.55 1 000 表 6 抱杆优化前后结果对比

Table 6. Results comparison before and after optimization for the holding pole

situation b1/mm t1/mm b2/mm t2/mm b3/mm t3/mm W/kg time T/s initial 150 12 70 5 70 5 43 335.21 24.06 IAOA 150 10 40 10 40 10 39 780.55 6×10−5 -

[1] 国家能源局. 架空输电线路施工抱杆通用技术条件及试验方法: DL/T 319—2018[S]. 北京: 中国电力出版社, 2018.National Energy Administration. General technical conditions and test methods for holding pole of overhead transmission line construction: DL/T 319—2018[S]. Beijing: China Electric Power Press, 2018. (in Chinese) [2] 池沛, 董军, 夏志远, 等. 架空输电线路摇臂抱杆应力状态分析及试验研究[J]. 钢结构, 2016, 31(10): 38-41 doi: 10.13206/j.gjg201610009CHI Pei, DONG Jun, XIA Zhiyuan, et al. Analysis and experimental study on the stress state of holding pole with double rotating arms for overhead transmission line construction[J]. Steel Construction, 2016, 31(10): 38-41.(in Chinese) doi: 10.13206/j.gjg201610009 [3] MENG Z, REN S H, WANG X, et al. System reliability-based design optimization with interval parameters by sequential moving asymptote method[J]. Structural and Multidisciplinary Optimization, 2021, 63: 1767-1788. doi: 10.1007/s00158-020-02775-1 [4] 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 起重机设计规范: GB/T3811—2008[S]. 北京: 中国标准出版社, 2008.General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China, Standardization Administration of the People’s Republic of China. Design rules for cranes: GB/T3811—2008[S]. Beijing: Standards Press of China, 2008. (in Chinese) [5] OSMAN I H, LAPORTE G. Metaheuristics: a bibliography[J]. Annals of Operations Research, 1996, 63: 513-623. [6] BAGHDADI A, HERISTCHIAN M, KLOFT H. Design of prefabricated wall-floor building systems using metaheuristic optimization algorithms[J]. Automation in Construction, 2020, 114: 103156. doi: 10.1016/j.autcon.2020.103156 [7] TAO R, MENG Z, ZHOU H L. A self-adaptive strategy based firefly algorithm for constrained engineering design problems[J]. Applied Soft Computing, 2021, 107: 107417. doi: 10.1016/j.asoc.2021.107417 [8] 孟建军, 孟高阳, 李德仓. 基于SA-GA混合算法的动车组车辆轮重分配优化[J]. 应用数学和力学, 2021, 42(4): 363-372MENG Jianjun, MENG Gaoyang, LI Decang. Optimization of weel weight distribution for EMU vehicles based on the SA-GA hybrid algroithm[J]. Applied Mathematics and Mechanics, 2021, 42(4): 363-372.(in Chinese) [9] ABUALIGAH L, DIABAT A, MIRJALILI S, et al. The arithmetic optimization algorithm[J]. Computer Methods in Applied Mechanics and Engineering, 2021, 376: 113609. doi: 10.1016/j.cma.2020.113609 [10] WOLPERT D H, MACREADY W G. No free lunch theorems for optimization[J]. IEEE Transactions on Evolutionary Computation, 1997, 1(1): 67-82. doi: 10.1109/4235.585893 [11] WANG R B, WANG W F, XU L, et al. An adaptive parallel arithmetic optimization algorithm for robot path planning[J]. Journal of Advanced Transportation, 2021, 2021: 3606895. [12] IZCI D, EKINCI S, KAYRI M, et al. A novel improved arithmetic optimization algorithm for optimal design of PID controlled and Bode’s ideal transfer function based automobile cruise control system[J]. Evolving Systems, 2022, 13(3): 1-16. [13] PIRES S E J, MACHADO T J A, OLIVEIRA P B D M, et al. Particle swarm optimization with fractional-order velocity[J]. Nonlinear Dynamics, 2010, 61: 295-301. doi: 10.1007/s11071-009-9649-y [14] MOUSAVI Y, ALFI A. Fractional calculus-based firefly algorithm applied to parameter estimation of chaotic systems[J]. Chaos, Solitons and Fractals, 2018, 114: 202-215. doi: 10.1016/j.chaos.2018.07.004 [15] DESHMUKH A B, RANI U N. Fractional-grey wolf optimizer-based kernel weighted regression model for multiview face video super resolution[J]. International Journal of Machine Learning and Cybernetics, 2019, 10: 859-877. doi: 10.1007/s13042-017-0765-6 [16] MEHMANI A, CHOWDHURY S, MEINRENKEN C, et al. Concurrent surrogate model selection (COSMOS): optimizing model type, kernel function, and hyper-parameters[J]. Structural and Multidisciplinary Optimization, 2018, 57: 1093-1114. doi: 10.1007/s00158-017-1797-y [17] FORRESTER A, SOBESTER A, KEANE A. Engineering Design via Surrogate Modelling: a Practical Guide[M]. UK: John Wiley and Sons, 2008. [18] GHAMISI P, COUCEIRO M S, BENEDIKTSSON J A, et al. An efficient method for segmentation of images based on fractional calculus and natural selection[J]. Expert Systems With Applications, 2012, 39(16): 12407-12417. doi: 10.1016/j.eswa.2012.04.078 [19] MUSTOE L R, BARRY M D J. Mathematics in Science and Engineering[M]. Elsevier, 1999. [20] 赵玉新, YANG Xinshe, 刘利强. 新兴元启发式优化方法[M]. 北京: 科学出版社, 2013.ZHAO Yuxin, YANG Xinshe, LIU Liqiang. Emerging Meta Heuristic Optimization Method[M]. Beijing: Science Press, 2013. (in Chinese) -

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号