Normalized Dynamic Characterization and Application of Multiple Heat Storage Materials Based on Standard Thermal Resistance

-

摘要:

基于标准热阻和能量流法,推导出储热材料与换热流体的瞬态换热热阻,通过类比电路分析法,获得了储热-换热过程的瞬态热量流模型及动态响应时间常数。进一步引入节点温度,重新定义换热热阻,获得了储热与换热过程耦合的三阶电路瞬态热量流模型,求解得到了加热、储热和释热三类时间常数,可用于协同表征储热材料中储热与释热的快慢程度,从而实现了多类储热材料的归一化动态表征。通过数值模拟验证与应用对比分析,发现基于多时间常数的归一化动态模型用于表征储热材料的动态特性是可行的,可直接对不同换热、储热材料进行对比分析。案例分析发现与固体储热材料换热时,液态金属的动态换热能力优于熔融盐,而相比于水蒸气和CO2,空气与陶瓷材料换热能更快达到稳态。

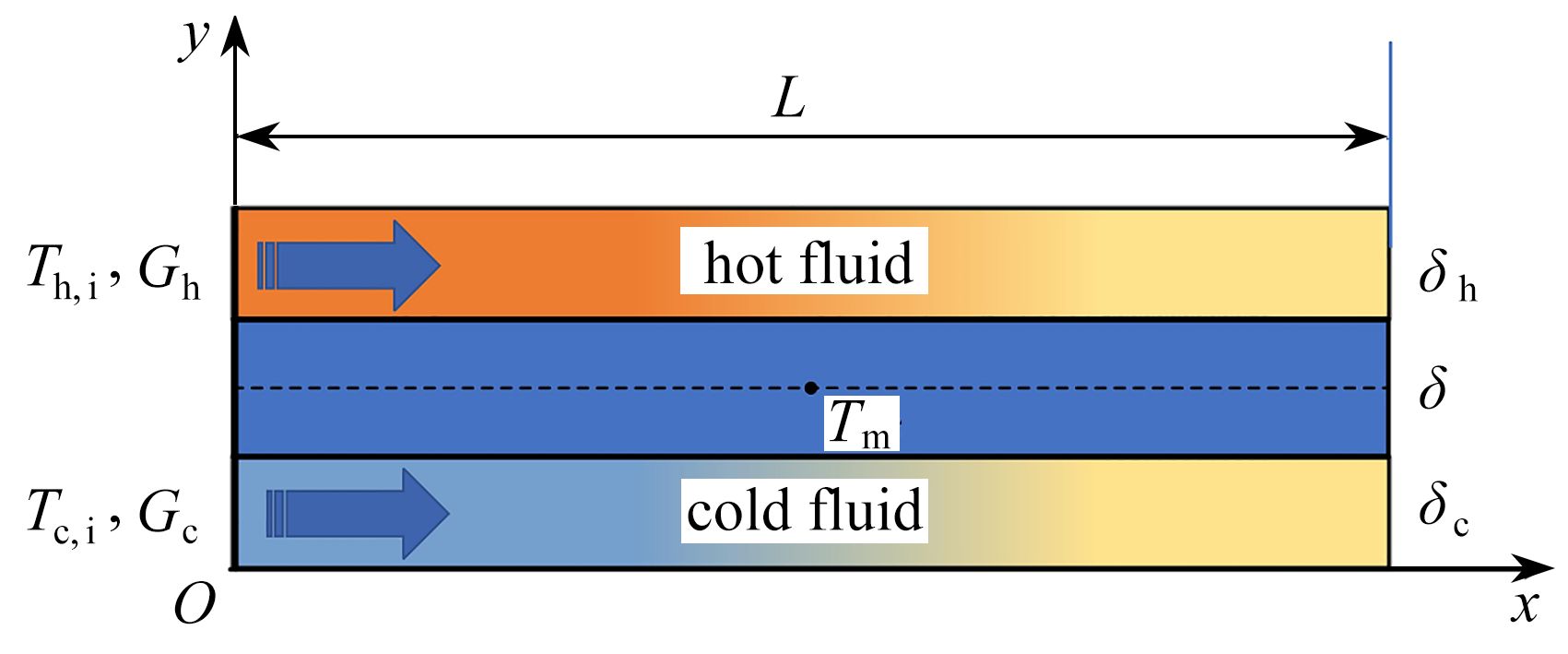

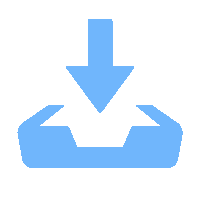

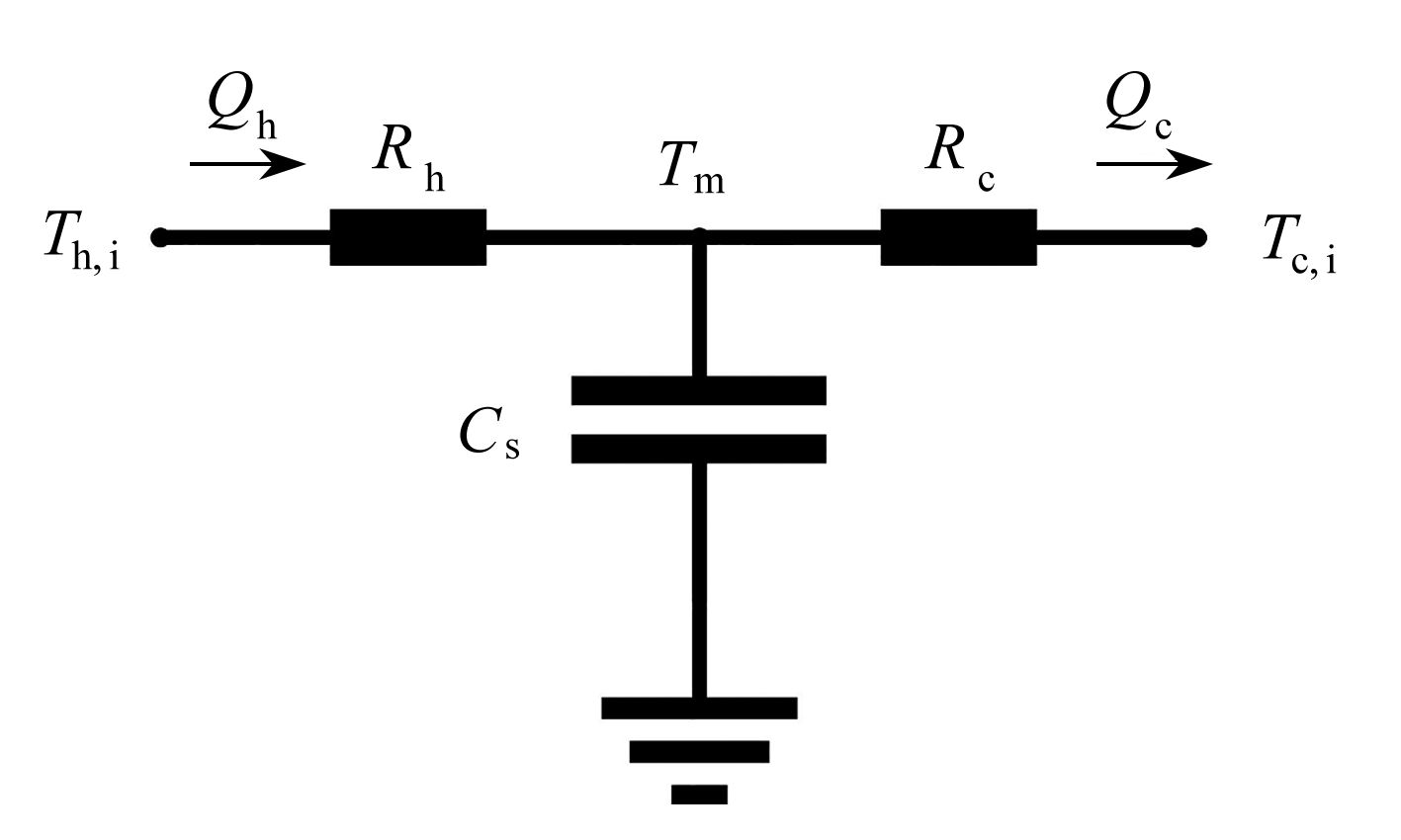

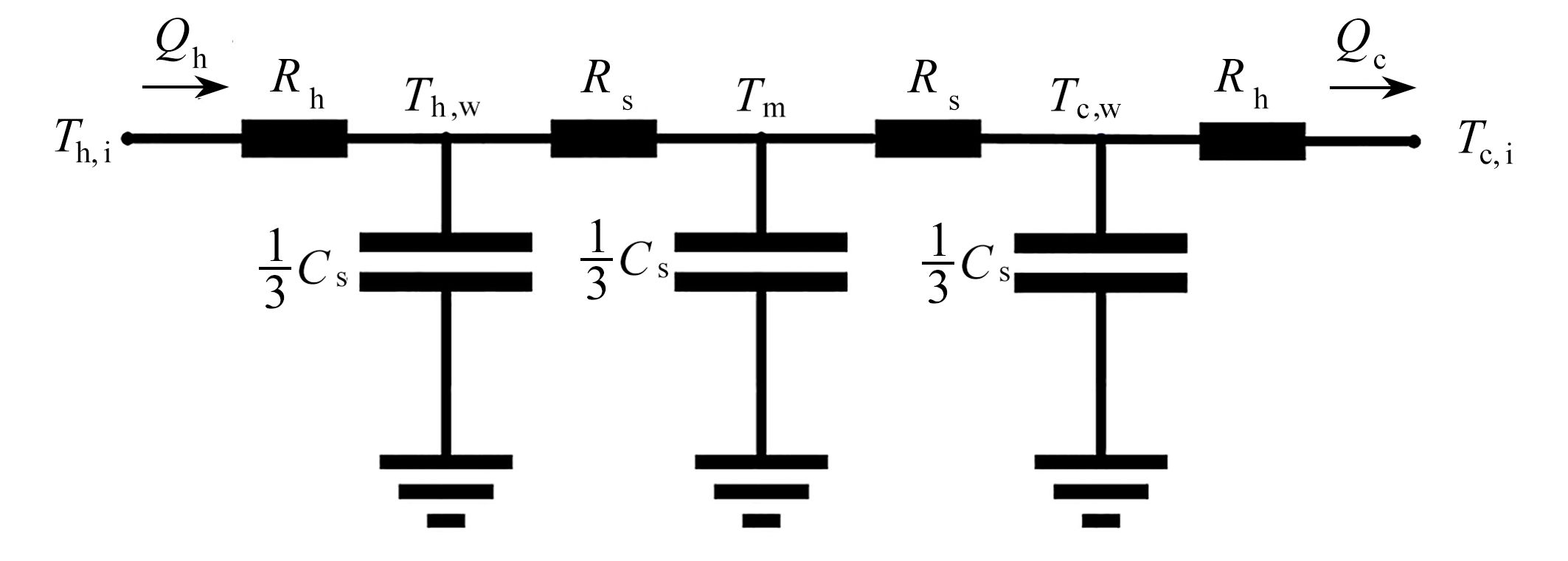

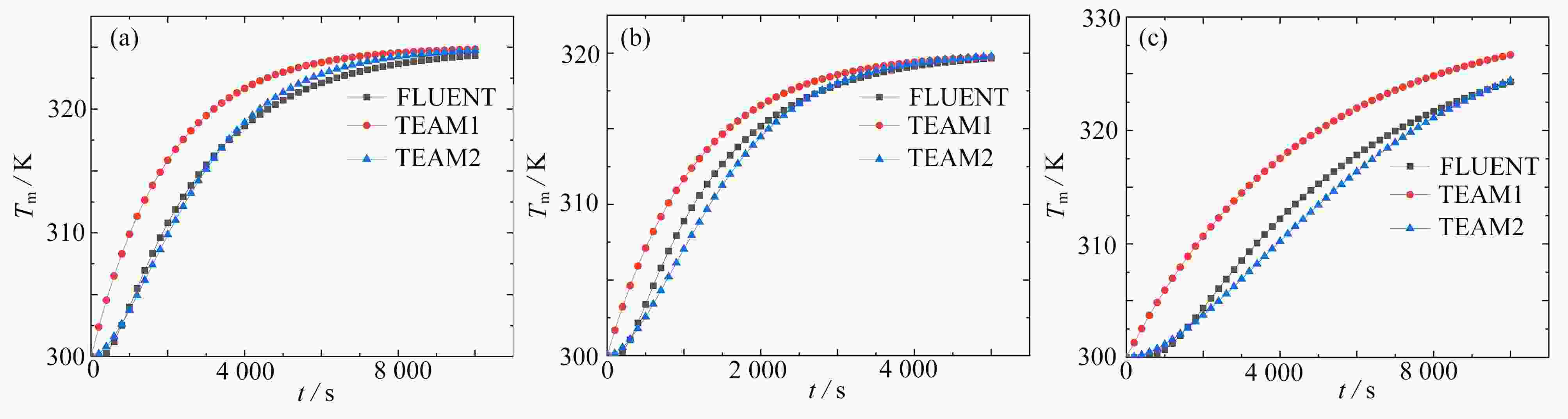

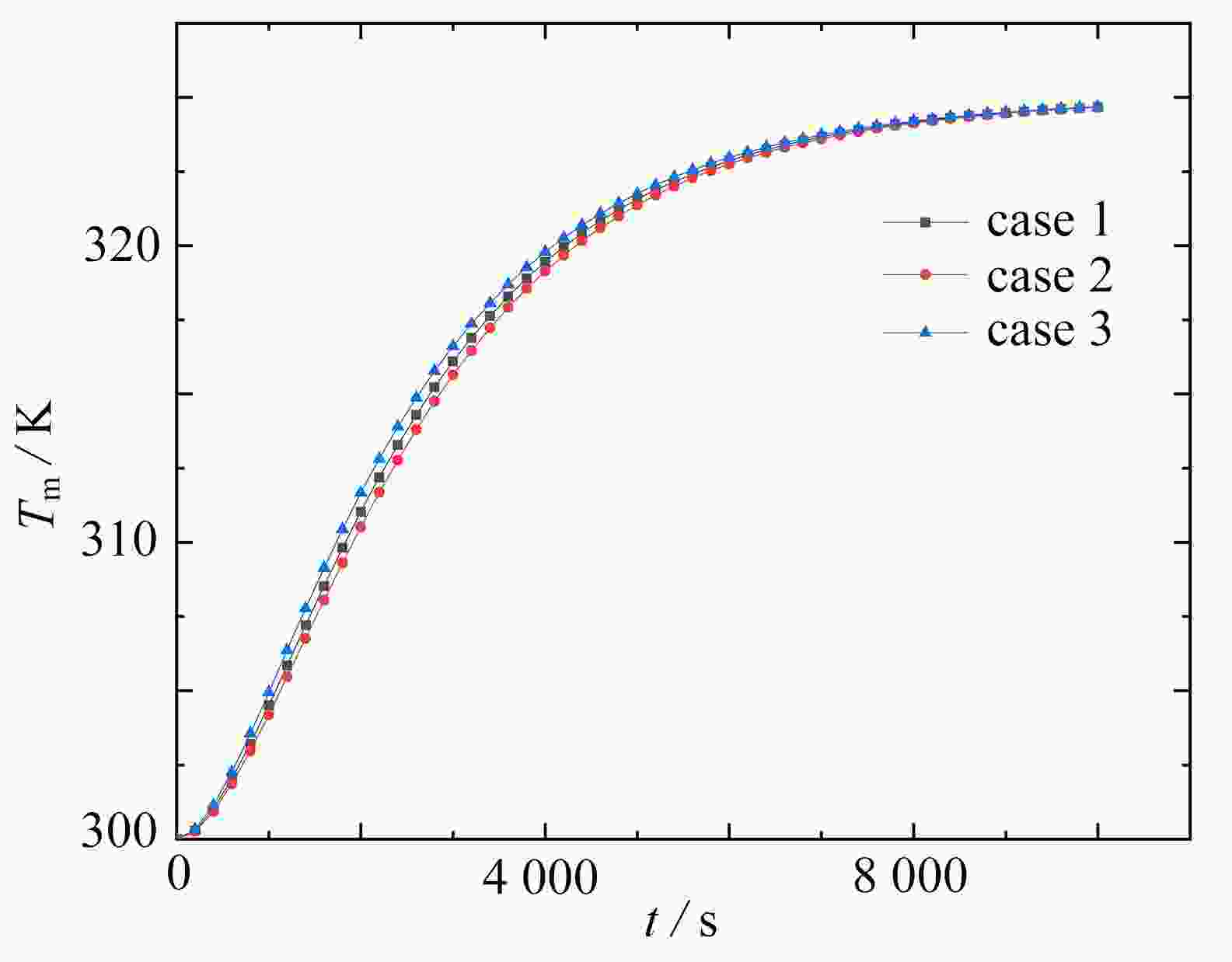

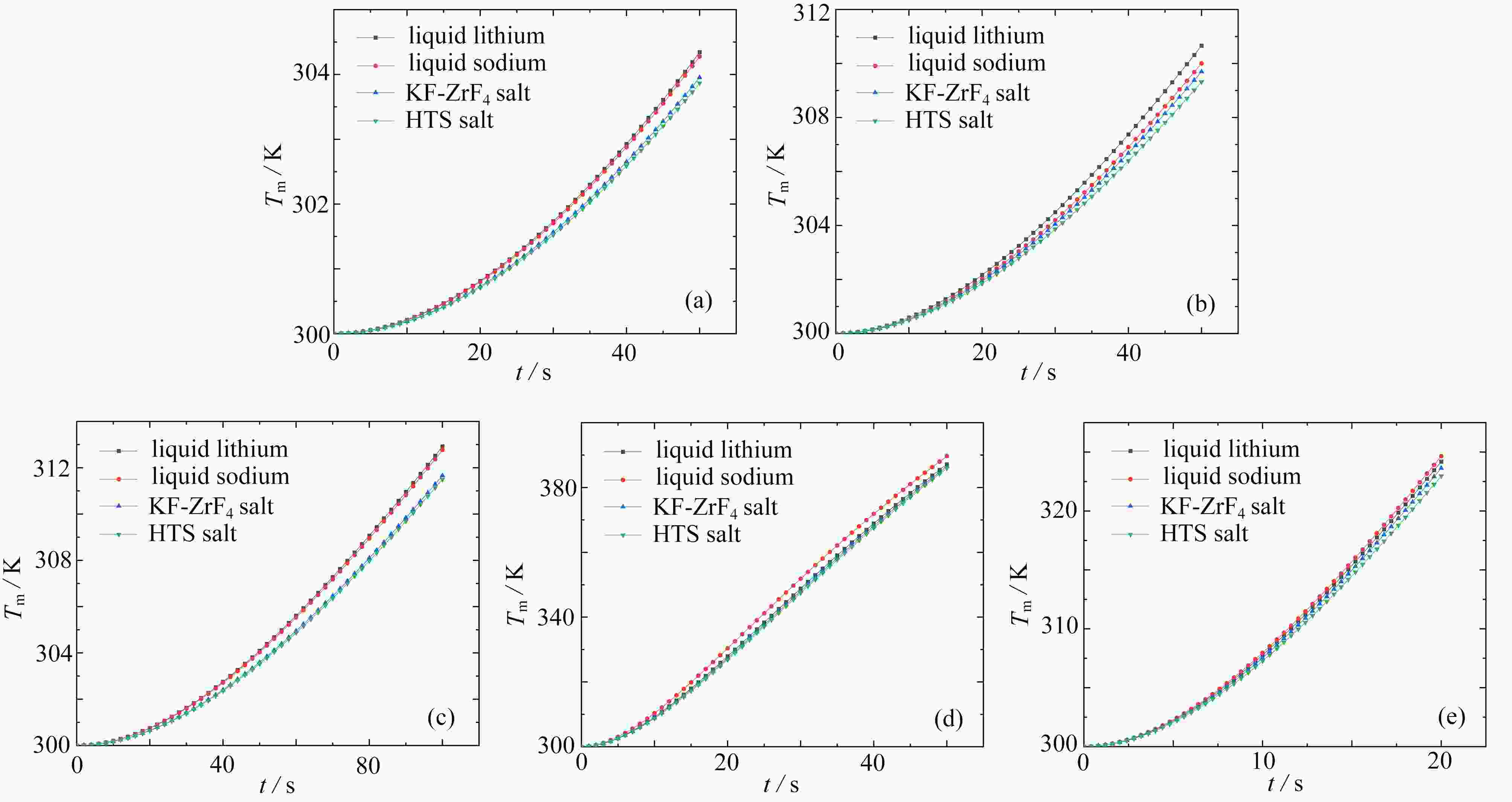

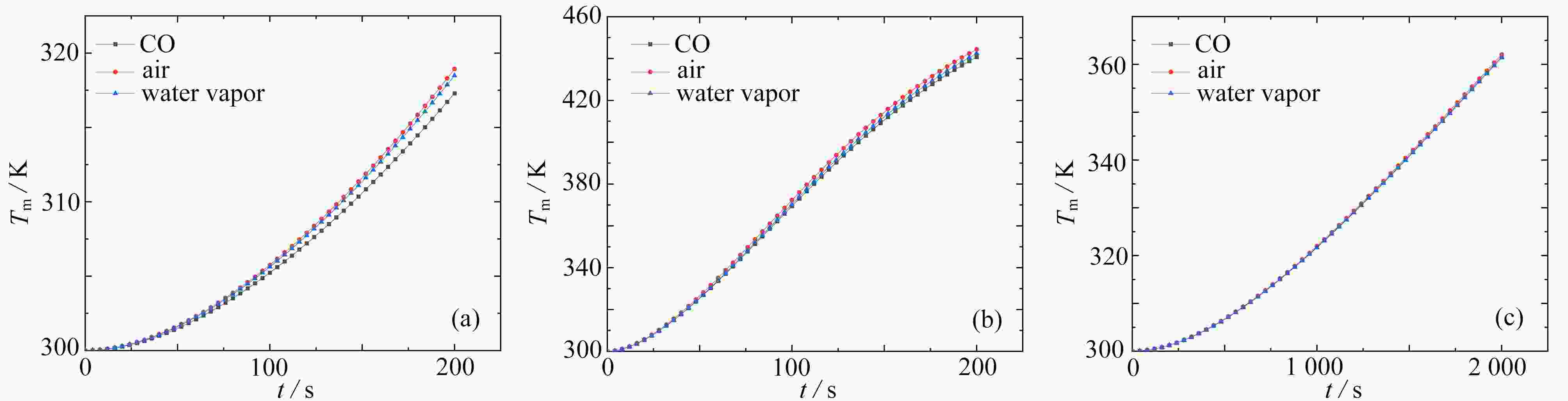

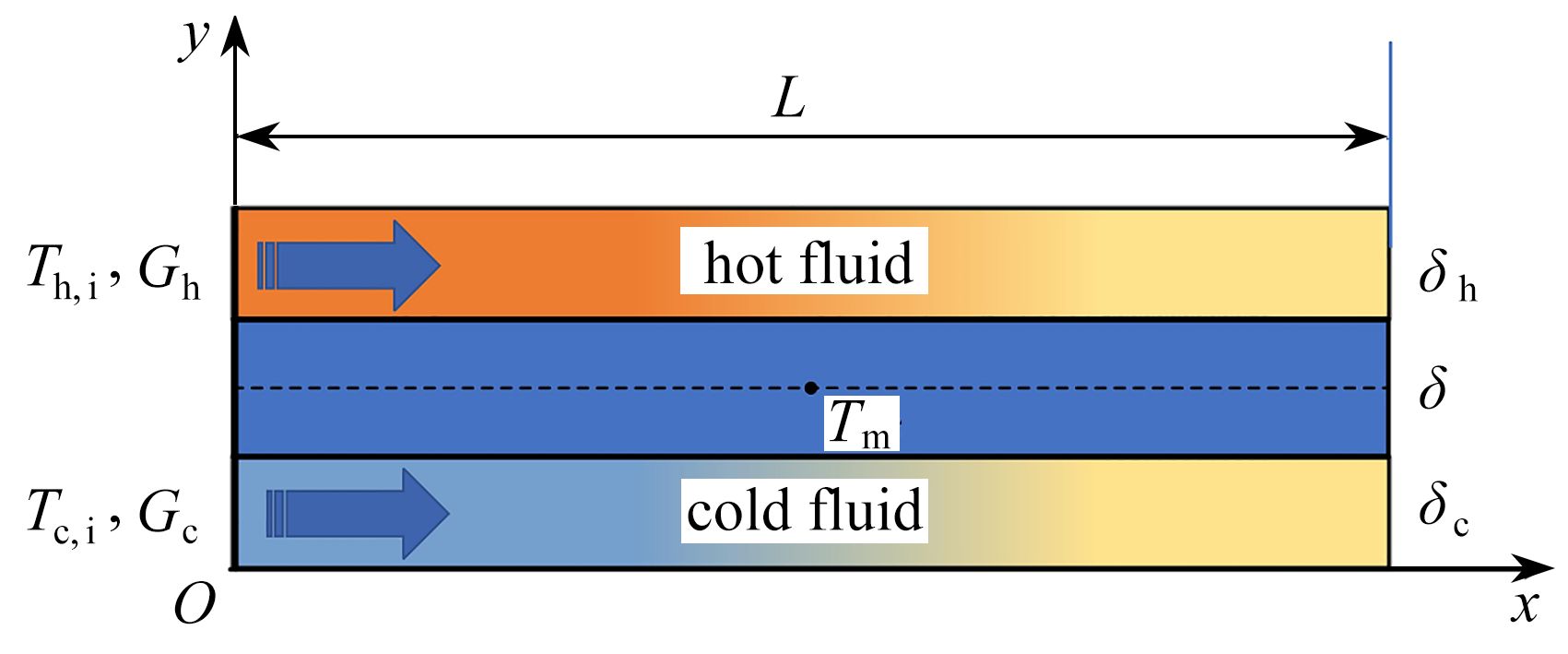

Abstract:Based on the standard thermal resistance and the heat current method, the transient heat transfer thermal resistance between the heat storage material and the heat transfer fluid was deduced. With the analog circuit analysis method, the transient heat current model and dynamic response time constants of heat storage-heat exchange processes were obtained. Based on this model, the node temperature was introduced for refining the heat transfer thermal resistance, and the transient heat current model for the 3rd-order circuit coupled with the heat storage and heat transfer processes was obtained. Numerical simulation verification and application comparison indicate that, the normalized dynamic model based on multiple time constants is feasible to characterize the dynamic characteristics of heat storage materials, and can directly compare and analyze different heat exchange and heat storage materials. The case study shows that, for the heat exchange with solid heat storage materials, the liquid metal has better dynamic heat exchange capacity than the molten salt, while for the heat exchange with ceramic materials, the air reaches the steady state faster than water vapor and CO2.

-

表 1 仿真验证设置

Table 1. Simulation verification settings

simulation

numberhot

fluidTh,i/K vh,i/(m·s−1) cold fluid Tc,i/K vc,i/(m·s−1) material δ/cm 1 water 350 2 water 300 1 CaCO3 15 2 water 340 2 benzene 300 1 CaO 10 3 water 360 3 benzene 300 1 CaSO4 10 表 2 时间常数

Table 2. Time constants

simulation number τh /s τm /s τc /s 1 1 323.27 1 997.37 1 323.40 2 758.55 962.79 758.55 3 3 047.15 4 222.93 3 047.15 表 3 三种情况下热流体物理性质及加热时间常数

Table 3. Physical properties and heating time constants of the thermal fluid in 3 cases

case ρ/(kg/m3) cp /(J·kg−1·K−1) λ /(W·m−1·K−1) τh /(s) 1 1 000 4 180 0.6 1 060.40 2 800 2 700 0.4 1 148.27 3 2 000 3 600 0.5 953.58 fluid ρ /(kg/m3)

cp /(J·kg−1·K−1)λ /(W·m−1·K−1) υ/(m2/s) liquid lithium 480 2 016 53 7.4×105 liquid sodium 830 1 045 66 2.9×105 KF-ZrF4 2 800 3 444 0.55 1.82×106 HTS 1 877 2 777 0.59 2.26×106 heat storage

materialdensity

ρ /(kg/m3)cp /(J∙kg−1∙K−1) thermal conductivity

λ /(W∙m−1·K−1)silicon refractory brick 1 820 1 000 1.5 magnesia refractory brick 3 000 1 150 5 reinforced concrete 2 200 850 1.5 cast iron 7 200 560 37 cast steel 7 800 600 40 表 6 加热时间常数(单位:s)

Table 6. Heating time constants (unit: s)

liquid lithium liquid sodium KF-ZrF4 salt HTS salt silicon refractory brick 98.46 99.67 106.33 108.29 magnesia refractory brick 63.66 64.68 65.50 66.32 reinforced concrete 98.96 100.58 108.95 109.25 cast iron 18.69 18.47 18.92 19.06 cast steel 21.12 21.02 21.19 21.36 ceramic material ρ /(kg/m3) cp /(J∙kg−1∙K−1) λ /(W∙m−1·K−1) quartz 2300 1140 11.5 silicon carbide 3100 1170 65.4 corundum 3200 1400 2.2 gas ρ /(kg/m3) cp /(J∙kg−1∙K−1) λ /(W∙m−1·K−1) υ/(m2/s) CO2 1.343 942 0.0251 1.466×107 air 0.524 1068 0.0521 6.309×107 water vapor 0.5549 2 009 0.027 2.392×107 表 9 加热时间常数(单位:s)

Table 9. Heating time constants (unit: s)

CO2 air water vapor quartz 298.31 292.28 296.26 silicon carbide 86.89 86.40 86.89 corundum 1638.53 1634.24 1640.83 -

[1] 陈海生, 李泓, 马文涛, 等. 2021年中国储能技术研究进展[J]. 储能科学与技术, 2021, 11(3): 1052-1076CHEN Haisheng, LI Hong, MA Wentao, et al. Research progress of energy storage technology in China in 2021[J]. Energy Storage Science and Technology, 2021, 11(3): 1052-1076.(in Chinese) [2] 姜竹, 邹博杨, 丛琳, 等. 储热技术研究进展与展望[J]. 储能科学与技术, 2021, 38(5): 1-26JIANG Zhu, ZOU Boyang, CONG Lin, et al. Recent progress and outlook of thermal energy storage technologies[J]. Energy Storage Science and Technology, 2021, 38(5): 1-26.(in Chinese) [3] 汪翔, 陈海生, 徐玉杰, 等. 储热技术研究进展与趋势[J]. 科学通报, 2017, 62(15): 1602-1610 doi: 10.1360/N972016-00663WANG Xiang, CHEN Haisheng, XU Yujie, et al. Advances and prospects in thermal energy storage: a critical review[J]. Chinese Science Bulletin, 2017, 62(15): 1602-1610.(in Chinese) doi: 10.1360/N972016-00663 [4] AL-SANEA S A, ZEDAN M F. Improving thermal performance of building walls by optimizing insulation layer distribution and thickness for same thermal mass[J]. Applied Energy, 2011, 88(9): 3113-3124. doi: 10.1016/j.apenergy.2011.02.036 [5] KURAVI S, TRAHAN J, RAHMAN M M, et al. Analysis of transient heat transfer in a thermal energy storage module[C]//Proceedings of the ASME 2010 International Mechanical Engineering Congress and Exposition. Vancouver, Canada, 2010: 1251-1258. [6] LI Q, BAI F, YANG B, et al. Dynamic simulations of a honeycomb ceramic thermal energy storage in a solar thermal power plant using air as the heat transfer fluid[J]. Applied Thermal Engineering, 2018, 129: 636-645. doi: 10.1016/j.applthermaleng.2017.10.063 [7] TAHER N B, BOUKADIDA N, LAJIMI N. Thermal response of a composite building envelope under the climatic conditions of Tunisia[C]//Proceedings of the 2018 9th International Renewable Energy Congress (IREC). Hammamet, Tunisia, 2018: 1-6. [8] 张荻, 郭帅, 谢永慧. 基于球窝结构冷却通道的强化传热数值及实验研究[J]. 应用数学和力学, 2014, 35(3): 254-263 doi: 10.3879/j.issn.1000-0887.2014.03.003ZHANG Di, GUO Shuai, XIE Yonghui. Numerical and experimental study of heat transfer enhancement based on the structure of cooling-channels with dimples[J]. Applied Mathematics and Mechanics, 2014, 35(3): 254-263.(in Chinese) doi: 10.3879/j.issn.1000-0887.2014.03.003 [9] 马令勇, 朱永健, 郑雨蒙, 等. 含石蜡玻璃屋顶动态传热性能分析[J]. 热科学与技术, 2018, 17(6): 444-448MA Lingyong, ZHU Yongjian, ZHENG Yumeng, et al. Analysis of dynamic heat transfer performance of glass roof containing paraffin[J]. Journal of Thermal Science and Technology, 2018, 17(6): 444-448.(in Chinese) [10] PEDERSEN C. An experimental study of the dynamic behavior and heat transfer characteristics of water droplets impinging upon a heated surface[J]. International Journal of Heat and Mass Transfer, 1970, 13(2): 369-381. doi: 10.1016/0017-9310(70)90113-4 [11] ARTMANN N, MANZ H, HEISELBERG P. Parametric study on the dynamic heat storage capacity of building elements[C]//Proceedings of the 28th AIVC Conference. Crete, Island, 2007 . [12] OZEL M. Effect of insulation location on dynamic heat-transfer characteristics of building external walls and optimization of insulation thickness[J]. Energy and Buildings, 2014, 72: 288-295. doi: 10.1016/j.enbuild.2013.11.015 [13] 李长玉, 方彦奎, 刘福旭, 等. 热防护服-空气-皮肤热传导模型及其解析解[J]. 应用数学和力学, 2021, 42(2): 162-169LI Changyu, FANG Yankui, LIU Fuxu, et al. A thermal protective clothing-air-skin heat conduction model and its analytical solution[J]. Applied Mathematics and Mechanics, 2021, 42(2): 162-169.(in Chinese) [14] 周保良, 李志远, 黄丹. 二维瞬态热传导的PDDO分析[J]. 应用数学和力学, 2022, 43(6): 660-668ZHOU Baoliang, LI Zhiyuan, HUANG Dan. PDDO analysis of 2D transient heat conduction problems[J]. Applied Mathematics and Mechanics, 2022, 43(6): 660-668.(in Chinese) [15] OLIVETI G, ARCURI N, MAZZEO D, et al. A new parameter for the dynamic analysis of building walls using the harmonic method[J]. International Journal of Thermal Sciences, 2015, 88: 96-109. doi: 10.1016/j.ijthermalsci.2014.09.006 [16] FRAISSE G, VIARDOT C, LAFABRIE O, et al. Development of a simplified and accurate building model based on electrical analogy[J]. Energy and Buildings, 2002, 34(10): 1017-1031. doi: 10.1016/S0378-7788(02)00019-1 [17] LIU Y, LI L, WANG J. A novel relation for heat flow using Maxwell thermoelectricity analogy[J]. International Communications in Heat and Mass Transfer, 2020, 117: 104745. doi: 10.1016/j.icheatmasstransfer.2020.104745 [18] 陈群, 郝俊红, 付荣桓, 等. 基于(火 积)理论的热系统分析和优化的能量流法[J]. 工程热物理学报, 2017, 38(7): 1376-1383CHEN Qun, HAO Junhong, FU Ronghuan, et al. Entransy-based power flow method for analysis and optimization of thermal systems[J]. Journal of Engineering Thermophysics, 2017, 38(7): 1376-1383.(in Chinese) [19] CHEN Q, HAO J H, ZHAO T. An alternative energy flow model for analysis and optimization of heat transfer systems[J]. International Journal of Heat and Mass Transfer, 2017, 108: 712-720. doi: 10.1016/j.ijheatmasstransfer.2016.12.080 [20] CHEN Q, FU R H, XU Y C. Electrical circuit analogy for heat transfer analysis and optimization in heat exchanger networks[J]. Applied Energy, 2015, 139: 81-92. doi: 10.1016/j.apenergy.2014.11.021 [21] ZHAO T, MIN Y, CHEN Q, et al. Electrical circuit analogy for analysis and optimization of absorption energy storage systems[J]. Energy, 2016, 104: 171-183. doi: 10.1016/j.energy.2016.03.120 [22] HE K L, CHEN Q, LIU Y T, et al. A transient heat current model for dynamic performance analysis and optimal control of heat transfer system[J]. International Journal of Heat and Mass Transfer, 2019, 145: 118767. doi: 10.1016/j.ijheatmasstransfer.2019.118767 [23] 邵卫, 陈群, 贺克伦, 等. 换热器动态特性分析的热量流模型[J]. 工程热物理学报, 2020, 41(11): 2828-2833SHAO Wei, CHEN Qun, HE Kelun, et al. Heat current model for analying the dynamic characteristic of heat exchangers[J]. Journal of Engineering Thermophysics, 2020, 41(11): 2828-2833.(in Chinese) [24] DUAN J, LI N, PENG J, et al. Full-response model of transient heat transfer of building walls using thermoelectric analogy method[J]. Journal of Building Engineering, 2022, 46: 103717. doi: 10.1016/j.jobe.2021.103717 [25] HE K L, CHEN Q, DONG E F, et al. An improved unit circuit model for transient heat conduction performance analysis and optimization in multi-layer materials[J]. Applied Thermal Engineering, 2018, 129: 1551-1562. doi: 10.1016/j.applthermaleng.2017.10.149 [26] 杨婧, 唐岚, 赵开联, 等. 基于热电比拟模型的电热综合能源优化调度[J]. 电力科学与工程, 2022, 38(5): 60-67 doi: 10.3969/j.ISSN.1672-0792.2022.05.008YANG Jing, TANG Lan, ZHAO Kailian, et al. Optimization scheduling of integrated electric heating energy system based on thermoelectric analogy model[J]. Electric Power Science and Engineering, 2022, 38(5): 60-67.(in Chinese) doi: 10.3969/j.ISSN.1672-0792.2022.05.008 [27] 谢刚. 熔融盐理论与应用[M]. 北京: 冶金工业出版社, 1998.XIE Gang. Theory and Application of Molten Salt[M]. Beijing: Metallurgical Industry Press, 1998. (in Chinese) [28] GEYER M. Thermal Storage for Solar Power Plants[M]. Springer, 1991: 199-214. [29] 任雪潭, 曾令可, 刘艳春, 等. 蓄热储能多孔陶瓷材料[J]. 陶瓷学报, 2006, 27(2): 217-226 doi: 10.3969/j.issn.1000-2278.2006.02.013REN Xuetan, ZENG Lingke, LIU Yanchun, et al. Porous ceramic materials for heat and energy storage[J]. Journal of Ceramics, 2006, 27(2): 217-226.(in Chinese) doi: 10.3969/j.issn.1000-2278.2006.02.013 [30] 李爱菊, 王毅, 张仁元, 等. 蓄热室新型蓄热体的研究进展[J]. 冶金能源, 2007, 36(1): 43-48 doi: 10.3969/j.issn.1001-1617.2007.03.012LI Aiju, WANG Yi, ZHANG Renyuan, et al. Research deveiopment of new type regenerative materials in regenerator chamber[J]. Energy for Metallurgical Industry, 2007, 36(1): 43-48.(in Chinese) doi: 10.3969/j.issn.1001-1617.2007.03.012 [31] 陶文铨. 传热学[M]. 5版. 北京: 高等教育出版社, 2018.TAO Wenquan. Heat Transfer[M]. 5th ed. Beijing: Higher Education Press, 2018. (in Chinese) -

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号