| [1] |

LUO X, WANG J H, DOONER M, et al. Overview of current development in electrical energy storage technologies and the application potential in power system operation[J]. Applied Energy, 2015, 137: 511-536. doi: 10.1016/j.apenergy.2014.09.081

|

| [2] |

OPEYEMI B M. Path to sustainable energy consumption: the possibility of substituting renewable energy for non-renewable energy[J]. Energy, 2021, 228: 120519. doi: 10.1016/j.energy.2021.120519

|

| [3] |

SHAMBERGER P J, BRUNO N M. Review of metallic phase change materials for high heat flux transient thermal management applications[J]. Applied Energy, 2020, 258: 113955. doi: 10.1016/j.apenergy.2019.113955

|

| [4] |

XU H T, WANG N, ZHANG C Y, et al. Energy conversion performance of a PV/T-PCM system under different thermal regulation strategies[J]. Energy Conversion and Management, 2021, 229: 113660. doi: 10.1016/j.enconman.2020.113660

|

| [5] |

MAHMOUD M, RAMADAM M, PULLEN K, et al. Waste Heat Recovery Applications Incorporating Phase Change Materials[M]//Reference Module in Materials Science and Materials Engineering. Elsevier, 2021.

|

| [6] |

黄钦, 余凌峰, 陈凯. 相变材料耦合冷板电池热管理系统的优化设计[J]. 应用数学和力学, 2022, 43(11): 1195-1202. doi: 10.21656/1000-0887.430278HUANG Qin, YU Lingfeng, CHEN Kai. Design of the battery thermal management system with phase change material coupled cold plates[J]. Applied Mathematics and Mechanics, 2022, 43(11): 1195-1202. (in Chinese) doi: 10.21656/1000-0887.430278

|

| [7] |

潘艾刚, 王俊彪, 张贤杰. 相变温控技术在航天热控领域中的应用现状及展望[J]. 材料导报, 2013, 27(23): 113-119.PAN Aigang, WANG Junbiao, ZHANG Xianjie. A review on development and applications of metal phase change technology in thermal control for aeronautics[J]. Materials Reports, 2013, 27(23): 113-119. (in Chinese)

|

| [8] |

HEYHAT M M, MOUSAVI S, SIAVASHI M. Battery thermal management with thermal energy storage composites of PCM, metal foam, fin and nanoparticle[J]. Journal of Energy Storage, 2020, 28: 101235. doi: 10.1016/j.est.2020.101235

|

| [9] |

AL-JETHELAH M, EBADI S, VENKATESHWAR K, et al. Charging nanoparticle enhanced bio-based PCM in open cell metallic foams: an experimental investigation[J]. Applied Thermal Engineering, 2019, 148: 1029-1042. doi: 10.1016/j.applthermaleng.2018.11.121

|

| [10] |

HUANG X P, SUN C, CHEN Z Q, et al. Experimental and numerical studies on melting process of phase change materials (PCMs) embedded in open-cells metal foams[J]. International Journal of Thermal Sciences, 2021, 170: 107151. doi: 10.1016/j.ijthermalsci.2021.107151

|

| [11] |

YANG B, ZHANG R R, GAO Z, et al. Effect of nanoparticles and metal foams on heat transfer properties of PCMs[J]. International Journal of Thermal Sciences, 2022, 179: 107567. doi: 10.1016/j.ijthermalsci.2022.107567

|

| [12] |

马预谱, 胡锦炎, 陈奇, 等. 金属材料增强的石蜡储热性能研究[J]. 工程热物理学报, 2016, 37(10): 2196-2201.MA Yupu, HU Jinyan, CHEN Qi, et al. Study on heat storage performance enhancement of paraffin by metallic material[J]. Journal of Engineering Thermophysics, 2016, 37(10): 2196-2201. (in Chinese)

|

| [13] |

CHEN L, WANG L, WANG Y F, et al. Influence of phase change material volume shrinkage on the cyclic process of thermal energy storage: a visualization study[J]. Applied Thermal Engineering: Design, Processes, Equipment, Economics, 2022, 203: 117776.

|

| [14] |

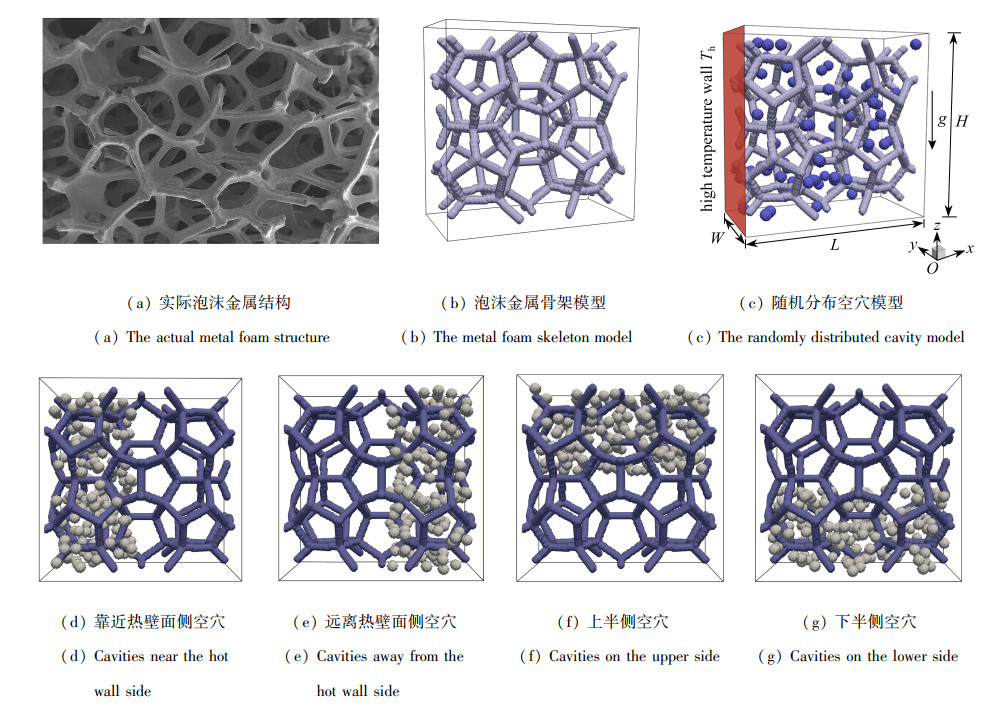

徐伟强, 袁修干, 邢玉明, 等. 空穴分布对固液相变蓄热过程的影响[J]. 太阳能学报, 2011, 32(2): 240-245.XU Weiqiang, YUAN Xiugan, XING Yuming, et al. Effects of void distribution on solid-liquid phase change thermal storage[J]. Acta Energiae Solaris Sinica, 2011, 32(2): 240-245. (in Chinese)

|

| [15] |

CHIEW J, CHIN C S, TOH W D, et al. Low-temperature macro-encapsulated phase change material based thermal energy storage system without air void space design[J]. Applied Thermal Engineering, 2018, 141: 928-938. doi: 10.1016/j.applthermaleng.2018.06.060

|

| [16] |

JANGHEL D, SAHA S K, KARAGADDE S. Effect of shrinkage void on thermal performance of pure and binary phase change materials based thermal energy storage system: a semi-analytical approach[J]. Applied Thermal Engineering, 2020, 167: 114706. doi: 10.1016/j.applthermaleng.2019.114706

|

| [17] |

SOLOMON L, ELMOZUGHI A F, OZTEKIN A, et al. Effect of internal void placement on the heat transfer performance-encapsulated phase change material for energy storage[J]. Renewable Energy, 2015, 78: 438-447. doi: 10.1016/j.renene.2015.01.035

|

| [18] |

LI X Y, NIU C, LI X X, et al. Pore-scale investigation on effects of void cavity distribution on melting of composite phase change materials[J]. Applied Energy, 2020, 275: 115302. doi: 10.1016/j.apenergy.2020.115302

|

| [19] |

CHEN L, KANG Q J, MU Y T, et al. A critical review of the pseudopotential multiphase lattice Boltzmann model: methods and applications[J]. International Journal of Heat and Mass Transfer, 2014, 76: 210-236. doi: 10.1016/j.ijheatmasstransfer.2014.04.032

|

| [20] |

SO R M C, LEUNG R C K, KAM E W S, et al. Progress in the development of a new lattice Boltzmann method[J]. Computers & Fluids, 2019, 190: 440-469.

|

| [21] |

REN Q L, CHAN C. GPU accelerated numerical study of PCM melting process in an enclosure with internal fins using lattice Boltzmann method[J]. International Journal of Heat and Mass Transfer, 2016, 100: 522-535. doi: 10.1016/j.ijheatmasstransfer.2016.04.059

|

| [22] |

HUANG R Z, WU H Y, CHENG P. A new lattice Boltzmann model for solid-liquid phase change[J]. International Journal of Heat and Mass Transfer, 2013, 59: 295-301. doi: 10.1016/j.ijheatmasstransfer.2012.12.027

|

| [23] |

LI D, TONG Z X, REN Q L, et al. Three-dimensional lattice Boltzmann models for solid-liquid phase change[J]. International Journal of Heat & Mass Transfer, 2017, 115(Part B): 1334-1347.

|

| [24] |

YOSHIDA H, KOBAYASHI T, HAYASHI H, et al. Boundary condition at a two-phase interface in the lattice boltzmann method for the convection-diffusion equation[J]. Physical Review E, 90(1): 013303.

|

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号