Breakup and Atomization Characteristics of Liquid Jets in Strong Swirling Crossflow Based on the VOF-LPT Method

-

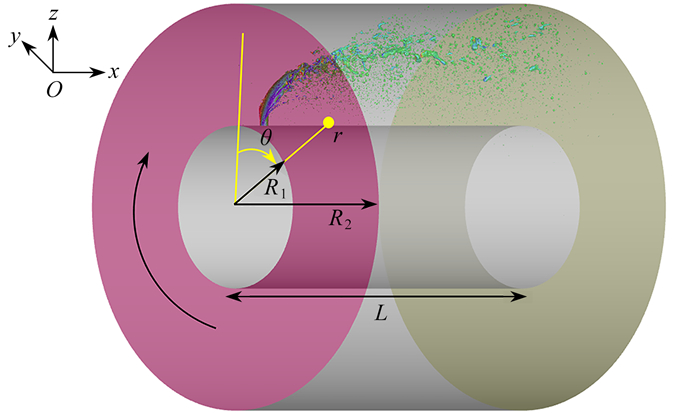

摘要: 研究强旋来流条件横向液体射流的破碎雾化特征对先进航发燃烧室设计具有重要意义. 该文采用Euler-Lagrange方法模拟了射流破碎雾化过程,基于VOF(volume of fluid)方法捕获了近场射流破碎过程中相界面的拓扑结构变化,通过Lagrange粒子追踪(LPT)方法模化喷雾液滴的动力学过程得到远场油雾分布特征. 该研究构建了不同旋流强度横向来流,旋流数从0变化至2.5,射流与气流的动量比q为10,来流We数为39. 在该工况下,射流破碎过程包含柱状破碎和表面破碎. 结果表明,由Kelvin-Helmholtz(KH)不稳定诱导的轴向波的发展是射流发生柱状破碎的主要原因,而射流分支/液膜从液柱表面剥离形成了射流的表面破碎,其主要由方位剪切不稳定波主导. 强旋流加速了射流的柱状破碎过程,降低了破碎位置的径向高度,但旋流延迟了射流的表面破碎过程,破碎开始位置的径向高度随旋流数增大而升高. 随着旋流数的增大,流向方向速度分量不断减小,射流沿径向方向的喷注轨迹显著升高;射流的偏转角度与流向位置呈线性关系,旋流数越大偏转斜率越大. 此外,射流雾化场的Sauter直径(SMD)随旋流数的增加而减小,液雾场的空间分布区域也随旋流数的增加而增大.Abstract: The liquid jet breakup and atomization interacting with a strong swirling crossflow is of significance in designing advanced aeroengines. The Eulerian-Lagrangian method was utilized to simulate the jet breakup and atomization processes. The volume of fluid (VOF) method was employed to track the gas-liquid interface topology evolution during the jet breakup, while the Lagrangian particle tracing (LPT) method was used to track the discrete droplets and obtain the information on far-field liquid dispersion. The crossflow was designed with different swirl numbers, ranging from 0 to 2.5. Momentum ratio q between the liquid jet and the air flow was set to 10, and the gas Weber number was 39. Under these conditions, both the column and shear breakups were observed. The results indicate that, the development of axial waves induced by the Kevin-Helmholtz (KH) instability was the main cause for column breakup. During the surface breakup, ligaments and small liquid jet branches were stripped from the liquid jet surface, primarily driven by azimuthal shear waves. The strong swirling airflow enhances the jet column breakup process, leading to a lower radial height for the breakup location and a shorter breakup time. However, as the swirl number increases, the radial height of the onset of breakup would increase, which suggests the swirl flow would delay the surface breakup of liquid jets. With the increase of the swirl number, the velocity component in the flow direction decreases, and the jet trajectory in the radial direction increases significantly. The deflection angle of the jet shows a linear relationship with the position of the flow direction, with larger air swirl numbers resulting in a steeper slope. Furthermore, as the swirl number increases, the Sauter mean diameter (SMD) of the entire spray field would decrease, and the liquid dispersion would increase.

-

Key words:

- swirling crossflow /

- liquid jet /

- VOF /

- LPT /

- breakup and atomization characteristic

-

表 1 射流液体以及来流气体物理性质

Table 1. Liquid and gas properties

parameter value gas density ρg/(kg/m3) 1.25 gas viscosity μg/(m2/s) 1.46E-5 liquid density ρl/(kg/m3) 997 liquid viscosity μl/(m2/s) 1.01E-6 surface tension coefficient σ/(N/m) 0.071 表 2 不同旋流数下空气来流与射流的工况设置

Table 2. Numerical setups for different swirling numbers

cases Ns Ug/(m/s) u/(m/s) v/(m/s) Ul/(m/s) case 0 0 74 74.00 0.00 8.29 case 1 0.5 74 68.62 27.71 8.29 case 2 1 74 57.57 46.50 8.29 case 3 2.5 74 32.84 66.31 8.29 表 3 不同旋流度下射流SMD结果

Table 3. Jet SMD results under different swirling numbers

cases Ns dSMD/μm case 0 0 60.80 case 1 0.5 52.66 case 2 1 48.94 case 3 2.5 48.15 表 4 不同位置截面射流SMD结果

Table 4. Jet SMD results at different cross sections

cases x/d=10 x/d=20 x/d=30 x/d=40 dSMD case 0 55.21 60.75 64.91 59.34 60.80 case 1 49.02 55.26 54.94 51.75 52.66 case 2 49.29 49.06 49.49 46.06 48.94 case 3 50.03 47.94 46.56 45.03 48.15 -

[1] URZAY J. Supersonic combustion in air-breathing propulsion systems for hypersonic flight[J]. Annual Review of Fluid Mechanics, 2018, 50: 593-627. doi: 10.1146/annurev-fluid-122316-045217 [2] 林宇震, 李林, 张弛, 等. 液体射流喷入横向气流混合特性研究进展[J]. 航空学报, 2014, 35(1): 46-57. https://www.cnki.com.cn/Article/CJFDTOTAL-HKXB201401004.htmLIN Yuzhen, LI Lin, ZHANG Chi, et al. Progress on the mixing of liquid jet injected into a crossflow[J]. Acta Aeronautica et Astronautica Sinica, 2014, 35(1): 46-57. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-HKXB201401004.htm [3] JENNY P, ROEKAERTS D, BEISHUIZEN N. Modeling of turbulent dilute spray combustion[J]. Progress in Energy and Combustion Science, 2012, 38(6): 846-887. doi: 10.1016/j.pecs.2012.07.001 [4] XIAO F, DIANAT M, MCGUIRK J J. Large eddy simulation of liquid-jet primary breakup in air crossflow[J]. AIAA Journal, 2013, 51(12): 2878-2893. doi: 10.2514/1.J052509 [5] HERRMANN M, ARIENTI M, SOTERIOU M. The impact of density ratio on the liquid core dynamics of a turbulent liquid jet injected into a crossflow[J]. Journal of Engineering for Gas Turbines and Power, 2011, 133(6): 061501-061510. doi: 10.1115/1.4002273 [6] 袁朝华. 非均匀横向气流场中的射流雾化现象研究[D]. 硕士学位论文. 天津: 中国民航大学, 2018.YUAN Chaohua. Study on jet breakup in non-uniform air crossflow field[D]. Master Thesis. Tianjin: Civil Aviation University of China, 2018. (in Chinese) [7] WU P K, KIRKENDALL K A, FULLER R P, et al. Breakup processes of liquid jets in subsonic crossflows[J]. Journal of Propulsion and Power, 1997, 13(1): 64-73. doi: 10.2514/2.5151 [8] FAETH G M. Liquid atomization in multiphase flows: a review[C]// 30th Fluid Dynamics Conference. Norfolk, VA, 1999. [9] 刘静, 徐旭. 高速气流中横向液体射流雾化研究进展[J]. 力学进展, 2009, 39(3) : 273-283.LIU Jing, XU Xu. The research development of liquid jet atomization in high speed crossflow[J]. Advances in Mechanics, 2009, 39(3): 273-283. (in Chinese) [10] SALLAM K A, AALBURG C, FAETH G M. Breakup of round nonturbulent liquid jets in gaseous crossflow[J]. AIAA Journal, 2004, 42(12): 2529-2540. doi: 10.2514/1.3749 [11] BEHZAD M, ASHGRIZ N, MASHAYEK A. Azimuthal shear instability of a liquid jet injected into a gaseous cross-flow[J]. Journal of Fluid Mechanics, 2015, 767: 146-172. doi: 10.1017/jfm.2015.36 [12] BROUMAND M, BIROUK M. Liquid jet in a subsonic gaseous crossflow: recent progress and remaining challenges[J]. Progress in Energy and Combustion Science, 2016, 57: 1-29. doi: 10.1016/j.pecs.2016.08.003 [13] BECKER J, HASSA C. Liquid fuel placement and mixing of generic aeroengine premix module at different operating conditions[J]. Journal of Engineering for Gas Turbines and Power, 2003, 125(4): 901-908. doi: 10.1115/1.1587741 [14] FREITAG S. Experimental investigations of fuel preparation in a swirling airflow under realistic conditions without reaction in a combustor model with a point fuel source[J]. CEAS Aeronautical Journal, 2018, 9(3): 475-490. doi: 10.1007/s13272-018-0295-2 [15] SIKRORIA T, KUSHARI A, SYED S, et al. Experimental investigation of liquid jet breakup in a cross flow of a swirling air stream[J]. Journal of Engineering for Gas Turbines and Power, 2014, 136(6): 061501. doi: 10.1115/1.4026244 [16] TAMBE S B, JENG S M. A study of liquid jets injected transversely into a swirling cross flow[C]//Proceedings of ILASS Americas, 21st Annual Conference on Liquid Atomization and Spray Systems. Orlando, FL, 2008. [17] MASUDA B J, MCDONELL V G, OSKAM G W. Mixing of a plain jet into a swirling crossflow[C]//Proceedings of ILASS Americas, 21st Annual Conference on Liquid Atomization and Spray Systems. Orlando, FL, 2008. [18] PATIL S, SAHU S. Air swirl effect on spray characteristics and droplet dispersion in a twin-jet crossflow airblast injector[J]. Physics of Fluids, 2021, 33(7): 073314. doi: 10.1063/5.0054430 [19] PRAKASH S R, JAIN S S, LOVETT J A, et al. Detailed numerical simulations of atomization of a liquid jet in a swirling gas crossflow[J]. Atomization and Sprays, 2019, 29(5): 1-17. [20] JIN T, WANG G, ZOU J, et al. Multiscale simulation of liquid jet breakup in swirling crossflows: breakup mechanism and spray structures[J]. SSRN Electronic Journal, 2022. DOI: 10.2139/ssrn.4092611. [21] XIAO H, GOLLNER M J, ORAN E S. From fire whirls to blue whirls and combustion with reduced pollution[J]. Proceedings of the National Academy of Sciences, 2016, 113(34): 9457-9462. doi: 10.1073/pnas.1605860113 [22] HEINRICH M, SCHWARZE R. 3D-coupling of volume-of-fluid and Lagrangian particle tracking for spray atomization simulation in OpenFOAM[J]. SoftwareX, 2020, 11: 100483. doi: 10.1016/j.softx.2020.100483 [23] TANGIRALA V, CHEN R H, DRISCOLL J F. Effect of heat release and swirl on the recirculation within swirl-stabilized flames[J]. Combustion Science and Technology, 1987, 51(1/3): 75-95. [24] BEHZAD M, ASHGRIZ N, KARNEY B W. Surface breakup of a non-turbulent liquid jet injected into a high pressure gaseous crossflow[J]. International Journal of Multiphase Flow, 2016, 80: 100-117. doi: 10.1016/j.ijmultiphaseflow.2015.11.007 [25] SHINJO J, UMEMURA A. Simulation of liquid jet primary breakup: dynamics of ligament and droplet formation[J]. International Journal of Multiphase Flow, 2010, 36(7): 513-532. doi: 10.1016/j.ijmultiphaseflow.2010.03.008 [26] XIE M, WU S, YU B, et al. Numerical investigation of the bifurcating behavior of liquid jets in crossflow[C]//Proceedings of ILASS Asia 22nd Annual Conference on Liquid Atomization and Spray Systems. 2022. [27] GOPALA Y, ZHANG P, BIBIK O, et al. Liquid fuel jet in crossflow-trajectory correlations based on the column breakup point[C]// 48th AIAA Aerospace Sciences Meeting Including the New Horizons Forum and Aerospace Exposition. Orlando, Florida, 2010. [28] MARMOTTANT P, VILLERMAUX E. On spray formation[J]. Journal of Fluid Mechanics, 2004, 498: 73-111. doi: 10.1017/S0022112003006529 -

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号