Structure Optimization of Holding Poles Based on the Improved Sine Cosine Algorithm

-

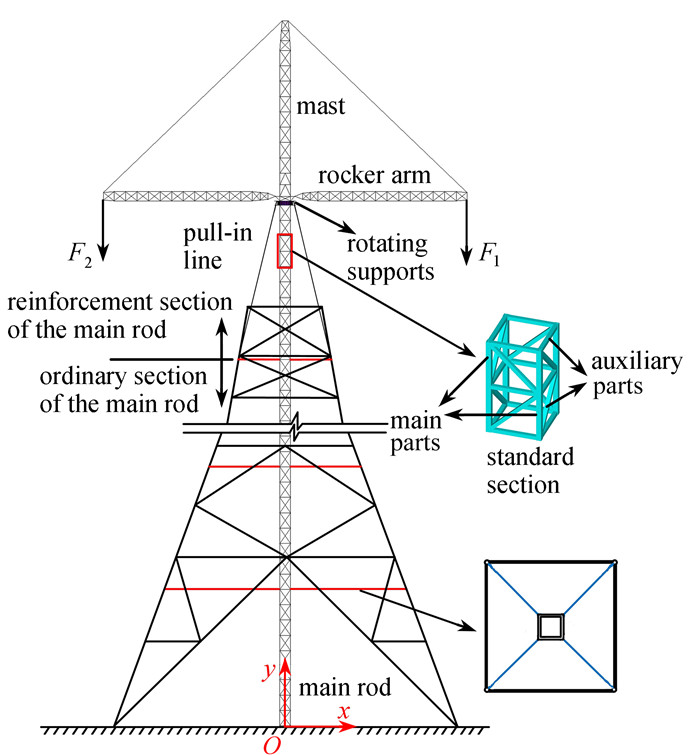

摘要: 抱杆是组立输电铁塔的特种起重设备. 以最小质量为优化目标,杆件的截面尺寸、辅材连接方式以及摇臂节点坐标为优化变量,许用应力、位移和屈曲系数为约束条件,建立抱杆优化设计模型. 提出一种改进的正余弦算法(improved sine cosine algorithm,ISCA),开展抱杆尺寸、形状和拓扑优化. 引入Lévy飞行增强算法全局搜索能力,采用精英引导策略增强算法局部搜索能力,使用贪婪选择策略更新最优解. 算例表明ISCA能够有效求解空间桁架结构的优化设计问题.Abstract: The holding pole is a special lifting device for the construction of transmission towers. The optimization design model for the holding pole was established. The minimum mass was set as the optimization objective. The cross-section sizes of members, the connection modes of auxiliary members and the coordinates of the rocker joint were set as the optimization variables. The allowable stress, displacement and buckling coefficient were taken as the constraining conditions. An improved sine cosine algorithm (ISCA) was proposed to carry out the size, shape and topology optimization designs of the holding pole. For the ISCA, the Lévy flight was introduced to enhance the global search ability, elite guidance strategy was applied to enhance the local search ability, and the greedy selection strategy was used to update the optimal solution. The example shows that, the ISCA can effectively solve the optimization design problems of spatial truss structures.

-

Key words:

- sine cosine algorithm /

- holding pole /

- truss structure /

- structure optimization /

- finite element analysis

edited-byedited-by1) (我刊编委周焕林来稿) -

表 1 抱杆各段角钢型号

Table 1. The angle steel model for each part of the holding pole

main part auxiliary part ordinary ∟80×6 ∟63×5 reinforcement ∟90×8 ∟63×5 mast ∟90×8 ∟60×6 rocker ∟65×6 ∟50×6 mass 13.64 t 表 2 载荷工况

Table 2. Load cases

load case lifted weight wind direction rocker orientation max unbalance loading case 1 4 t, 3 t 0° 45° case 2 4 t, 3 t 45° 45° case 3 4 t, 3 t 90° 45° high wind case 4 - 0° 45° case 5 - 45° 45° case 6 - 90° 45° 表 3 各工况分析结果

Table 3. Analysis results of each working condition

load case max Mises stress σm/MPa top displacement ut/mm buckling coefficient main part auxiliary part working case 1 166.53 76.47 259.82 4.01 case 2 169.19 84.48 268.47 3.93 case 3 168.41 75.15 248.93 4.00 high wind case 4 173.19 58.42 243.36 3.80 case 5 181.43 47.94 252.56 3.62 case 6 180.58 44.54 244.19 3.57 表 4 优化结果

Table 4. Optimization results

algorithm A1 A2 A3 A4 A5 A6 A7 A8 y1 y5 T1 T2 T3 T4 mass W/t ISCA ∟70×6 ∟45×3 ∟80×7 ∟45×3 ∟75×7 ∟45×3 ∟45×5 ∟45×4 80 -150 5 3 4 2 10.44 SCA ∟70×6 ∟45×3 ∟90×8 ∟45×4 ∟75×8 ∟50×6 ∟50×6 ∟50×5 90 -50 2 1 3 1 11.18 -

[1] 陶然, 周焕林, 孟增, 等. 基于响应面法和改进算术优化算法的抱杆优化设计[J]. 应用数学和力学, 2022, 43(10): 1113-1122. doi: 10.21656/1000-0887.420318TAO Ran, ZHOU Huanlin, MENG Zeng, et al. Optimization design of holding pole based on response surface methodology and improved arithmetic optimization algorithm[J]. Applied Mathematics and Mechanics, 2022, 43(10): 1113-1122. (in Chinese) doi: 10.21656/1000-0887.420318 [2] 方林, 蒋晓琳, 周庆丰, 等. 基于改进天鹰优化器的抱杆结构优化[J]. 科学技术与工程, 2023, 23(27): 11759-11767. doi: 10.12404/j.issn.1671-1815.2023.23.27.11759FANG Lin, JIANG Xiaolin, ZHOU Qingfeng, et al. Structure optimization of holding pole based on improved aquila optimizer[J]. Science Technology and Engineering, 2023, 23(27): 11759-11767. (in Chinese) doi: 10.12404/j.issn.1671-1815.2023.23.27.11759 [3] 刘宸宇, 骆烜赫, 刘康翔, 等. 基于平铺刚度法的弧形加筋板的轻量化设计[J]. 应用数学和力学, 2023, 44(8): 953-964. doi: 10.21656/1000-0887.430342LIU Chenyu, LUO Xuanhe, LIU Kangxiang, et al. Light weight design of arc rib stiffened plate based on the smeared stiffener method[J]. Applied Mathematics and Mechanics, 2023, 44(8): 953-964. (in Chinese) doi: 10.21656/1000-0887.430342 [4] 杜晨, 彭雄奇. 变厚度连续纤维增强复合材料铺层设计优化方法[J]. 应用数学和力学, 2022, 43(12): 1313-1323. doi: 10.21656/1000-0887.420410DU Chen, PENG Xiongqi. Lamination design optimization for continuous fiber reinforced composites of variable thicknesses[J]. Applied Mathematics and Mechanics, 2022, 43(12): 1313-1323. (in Chinese) doi: 10.21656/1000-0887.420410 [5] 郭惠勇, 宋小辉, 李正良. 基于改进人工鱼群算法的输电塔塔腿拓扑优化[J]. 振动与冲击, 2017, 36(4): 52-58. https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ201704009.htmGUO Huiyong, SONG Xiaohui, LI Zhengliang. Topology optimization of transmission tower legs based on an improved artificial fish-swarm algorithm[J]. Journal of Vibration and Shock, 2017, 36(4): 52-58. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ201704009.htm [6] 石开荣, 潘文智, 姜正荣, 等. 基于生长空间限定与并行搜索的模拟植物生长算法的空间结构优化方法[J]. 建筑结构学报, 2021, 42(7): 85-94. https://www.cnki.com.cn/Article/CJFDTOTAL-JZJB202107010.htmSHI Kairong, PAN Wenzhi, JIANG Zhengrong, et al. Optimization method of spatial structures based on growth space limited & parallel search-based plant growth simulation algorithm[J]. Journal of Building Structures, 2021, 42(7): 85-94. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-JZJB202107010.htm [7] SOUZA R R D, MIGUEL L F F, LOPEZ R H, et al. A procedure for the size, shape and topology optimization of transmission line tower structures[J]. Engineering Structures, 2016, 111: 162-184. doi: 10.1016/j.engstruct.2015.12.005 [8] KHODZHAIEV M, REUTER U. Structural optimization of transmission towers using a novel genetic algorithm approach with a variable length genome[J]. Engineering Structures, 2021, 240: 112306. doi: 10.1016/j.engstruct.2021.112306 [9] FIORE A, MARANO G C, GRECO R, et al. Structural optimization of hollow-section steel trusses by differential evolution algorithm[J]. International Journal of Steel Structures, 2016, 16(2): 411-423. doi: 10.1007/s13296-016-6013-1 [10] RENKAVIESKI C, PARPINELLI R S. Meta-heuristic algorithms to truss optimization: literature mapping and application[J]. Expert Systems With Applications, 2021, 182: 115197. doi: 10.1016/j.eswa.2021.115197 [11] MIRJALILI S. SCA: a sine cosine algorithm for solving optimization problems[J]. Knowledge-Based Systems, 2016, 96: 120-133. doi: 10.1016/j.knosys.2015.12.022 [12] ATTIA A F, EL SEHIEMY R A, HASANIEN H M. Optimal power flow solution in power systems using a novelsine-cosine algorithm[J]. International Journal of Electrical Power & Energy Systems, 2018, 99: 331-343. [13] EWEES A A, ELAZIZ M A, AL-QANESS M A A, et al. Improved artificial bee colony using sine-cosine algorithm for multi-level thresholding image segmentation[J]. IEEE Access, 2020, 8: 26304-26315. doi: 10.1109/ACCESS.2020.2971249 [14] ABUALIGAH L, DULAIMI A J. A novel feature selection method for data mining tasks using hybrid sine cosine algorithm and genetic algorithm[J]. Cluster Computing, 2021, 24(3): 2161-2176. doi: 10.1007/s10586-021-03254-y [15] ABDEL-MAWGOUD H, FATHY A, KAMEL S. An effective hybrid approach based on arithmetic optimization algorithm and sine cosine algorithm for integrating battery energy storage system into distribution networks[J]. Journal of Energy Storage, 2022, 49: 104154. doi: 10.1016/j.est.2022.104154 [16] LI N, WANG L. Bare-bones based sine cosine algorithm for global optimization[J]. Journal of Computational Science, 2020, 47: 101219. doi: 10.1016/j.jocs.2020.101219 [17] LONG W, WU T, LIANG X, et al. Solving high-dimensional global optimization problems using an improved sine cosine algorithm[J]. Expert Systems With Applications, 2019, 123: 108-126. doi: 10.1016/j.eswa.2018.11.032 [18] GANDOMI A H, YANG X S, ALAVI A H. Cuckoo search algorithm: a metaheuristic approach to solve structural optimization problems[J]. Engineering With Computers, 2013, 29(1): 17-35. doi: 10.1007/s00366-011-0241-y -

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号