Application of the Rate-Dependent Ladeveze Model in Failure Analysis of Composites

-

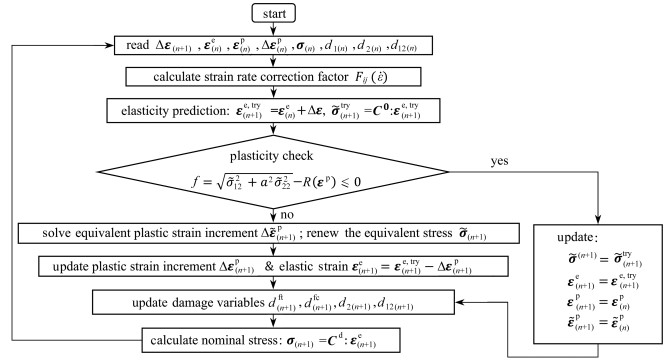

摘要: 为研究单向纤维增强复合材料在单轴载荷作用下的承载特性与失效模式差异,对复合材料单向板承载时的塑性累积与损伤演化等力学响应进行了有限元预测. 首先,引入基于2D连续介质损伤理论的Ladeveze本构模型,并将其看作平面应力问题. 考虑材料塑性行为的影响,并假定塑性强化为各向同性强化,利用FORTRAN编程语言对LS-DYNA进行二次开发,编写了基于Ladeveze损伤本构模型的用户材料子程序. 利用LS-DYNA建立复合材料单向板的有限元仿真模型,研究了其在承受纵向拉伸、纵向压缩、横向拉伸,面内剪切等载荷下的典型失效行为,并与试验结果进行了对比,然后对所编写子程序的有效性进行了验证. 最后,引入对数型率相关修正函数,对复合材料承受不同应变率载荷下的破坏行为进行了预测,研究了单向纤维增强复合材料率效应敏感度与承载组分之间的关系.

-

关键词:

- Ladeveze本构模型 /

- 损伤演化 /

- 率效应 /

- 塑性

Abstract: To investigate the load-bearing capacity and failure modes of unidirectional fiber-reinforced laminates subjected to uniaxial loads, finite element analyses were conducted to predict mechanical responses such as plastic accumulation and damage evolution. The Ladeveze constitutive model based on the 2D continuum damage theory was introduced and a user material subroutine was developed based on this model to consider the plastic behavior of the composites, where the isotropic plastic strengthening was assumed. Subsequently, a LS-DYNA finite element simulation model for unidirectional laminate plates was established to explore typical failure behaviors under loading conditions of longitudinal tension, longitudinal compression, transverse tension, and in-plane shear, respectively. A comparative analysis with experimental results was carried out to validate the efficacy of the developed subroutine. Finally, a logarithmic rate-dependent correction function was introduced to predict the damage modes of composite materials under various strain rate loads. The sensitivity of the rate effect in unidirectional fiber-reinforced laminates and its correlation with load-bearing components were investigated.-

Key words:

- Ladeveze constitutive model /

- damage evolution /

- rate effect /

- plasticity

other(Recommended by LIANG Xudong, M.AMM Youth Editorial Board)

1) (我刊青年编委梁旭东推荐) -

parameter value longitudinal tensile elastic modulus E1t/MPa 139 000 transverse elastic modulus E2/MPa 10 900 shear elastic modulus G12/MPa 6 000 longitudinal compressive elastic modulus E1c/MPa 139 000 Poisson’s ratio ν12 0.32 reduction coefficient of longitudinal compressive elastic modulus γ 1×10-5 initial value of debonding damage between fiber and matrix Y0/MPa 0.048 debonding damage limit between fiber and matrix YR/MPa 3.10 debonding damage evolution parameter between fiber and matrix Yc/MPa 1.745 initial value of transverse microcrack damage Y′0/MPa 0.07 damage limit value of transverse microcrack Y′S/MPa 2.75 damage evolution parameter of transverse microcrack Y′c/MPa 0.565 coupling strength of transverse tensile and shear b 0.53 initial strain of tensile damage in the fiber direction εift 0.014 8 tensile damage limit strain in the fiber direction εuft 0.014 9 tensile limit damage value in the fiber direction duft 0.99 initial strain of compression damage in the fiber direction εifc 0.008 compressive damage limit strain in the fiber direction εufc 0.008 5 compressive ultimate damage value in the fiber direction dufc 0.99 initial yield stress R0/MPa 21.59 hardening coefficient β 558 cementation index m 0.54 shear and transverse plastic strain coupling factor a 0.38 表 2 复合材料Ladeveze本构率相关部分参数[23]

Table 2. Parameters related to Ladeveze constitutive rates of composite materials[23]

parameter notation value longitudinal elastic modulus rate related parameters $ \dot{\varepsilon}_{11}^{\text {ref }} / \mathrm{s}^{-1}$ 3×10-4 D11 0.025 6 n11 -0.322 5 longitudinal failure strain rate related parameters $ \dot{\varepsilon}_{11}^{\text {ref }} / \mathrm{s}^{-1}$ 3×10-4 Du11 -0.018 nu11 0.338 5 transverse elastic modulus rate related parameters $ \dot{\varepsilon}_{22}^{\text {ref }} / \mathrm{s}^{-1}$ 3×10-4 D22 0.072 7 n22 -0.922 89 shear modulus rate related parameters $ \dot{\varepsilon}_{12}^{\text {ref }} / \mathrm{s}^{-1}$ 3×10-4 D12 0.032 9 n12 -0.420 8 yield stress rate related parameters $ \dot{\varepsilon}_{0}^{\text {ref }} / \mathrm{s}^{-1}$ 3×10-4 DR0 0.861 5 nR0 -1.872 1 -

[1] 陈静芬. 基于弹塑性损伤本构模型的复合材料层合板破坏荷载预测[J]. 复合材料学报, 2017, 34 (4): 773-785. https://www.cnki.com.cn/Article/CJFDTOTAL-FUHE201704011.htmCHEN Jingfen. Failure loads prediction of composite laminates using a combined elastic damage model[J]. Acta Materiae Compositae Sinica, 2017, 34 (4): 773-785. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-FUHE201704011.htm [2] TORO S, SÁNCHEZ P J, BLANCO P J, et al. Multiscale formulation for material failure accounting for cohesive cracks at the macro and micro scales[J]. International Journal of Plasticity, 2016, 76 : 75-110. doi: 10.1016/j.ijplas.2015.07.001 [3] CATALANOTTI G, CAMANHO P P, MARQUES A T. Three-dimensional failure criteria for fiber-reinforced laminates[J]. Composite Structures, 2013, 95 : 63-79. doi: 10.1016/j.compstruct.2012.07.016 [4] TSAI S W, MELO J D D. A unit circle failure criterion for carbon fiber reinforced polymer composites[J]. Composites Science and Technology, 2016, 123 : 71-78. doi: 10.1016/j.compscitech.2015.12.011 [5] VOGLER M, ROLFES R, CAMANHO P P. Modeling the inelastic deformation and fracture of polymer composites, part Ⅰ: plasticity model[J]. Mechanics of Materials, 2013, 59 : 50-64. doi: 10.1016/j.mechmat.2012.12.002 [6] LI N, GU J, CHEN P. Fracture plane based failure criteria for fibre-reinforced composites under three-dimensional stress state[J]. Composite Structures, 2018, 204 : 466-474. doi: 10.1016/j.compstruct.2018.07.103 [7] CHEVALIER J, MORELLE X P, BAILLY C, et al. Micro-mechanics based pressure dependent failure model for highly cross-linked epoxy resins[J]. Engineering Fracture Mechanics, 2016, 158 : 1-12. doi: 10.1016/j.engfracmech.2016.02.039 [8] SUN Q, MENG Z, ZHOU G, et al. Multi-scale computational analysis of unidirectional carbon fiber reinforced polymer composites under various loading conditions[J]. Composite Structures, 2018, 196 : 30-43. doi: 10.1016/j.compstruct.2018.05.025 [9] 刘鑫, 吴倩倩, 于国财, 等. 碳纤维/树脂基复合材料曲壁蜂窝夹芯结构的三点弯曲性能[J]. 应用数学和力学, 2022, 43 (5): 490-498. doi: 10.21656/1000-0887.430061 LIU Xin, WU Qianqian, YU Guocai, et al. Three-point bending properties of carbon fiber reinforced polymer composite honeycomb sandwich structures with curved wall[J]. Applied Mathematics and Mechanics, 2022, 43 (5): 490-498. (in Chinese) doi: 10.21656/1000-0887.430061 [10] 李汝鹏, 陈磊, 刘学术, 等. 基于渐进损伤理论的复合材料开孔拉伸失效分析[J]. 航空材料学报, 2018, 38 (5): 138-146. https://www.cnki.com.cn/Article/CJFDTOTAL-HKCB201805018.htmLI Rupeng, CHEN Lei, LIU Xueshu, et al. Progressive damage based failure analysis of open-hole composite laminates under tension[J]. Journal of Aeronautical materials, 2018, 38 (5): 138-146. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-HKCB201805018.htm [11] 李星, 关志东, 刘璐, 等. 基于应变不变量失效理论的复合材料损伤模拟[J]. 北京航空航天大学学报, 2013, 39 (2): 190-195. https://www.cnki.com.cn/Article/CJFDTOTAL-BJHK201302011.htmLI Xing, GUAN Zhidong, LIU Lu, et al. Damage simulation of composite materials based on strain invariant failure theory[J]. Journal of Beijing University of Aeronautics and Astronautics, 2013, 39 (2): 190-195. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-BJHK201302011.htm [12] 张超, 许希武, 郭树祥. 含界面脱粘三维五向编织复合材料单向拉伸损伤失效机理研究[J]. 航空材料学报, 2011, 31 (6): 73-80. https://www.cnki.com.cn/Article/CJFDTOTAL-HKCB201106014.htmZHANG Chao, XU Xiwu, GUO Shuxiang. Damage and failure mechanism analysis of 3D five-directional braided composites with interface debonding under unidirectional tension[J]. Journal of Aeronautical Materials, 2011, 31 (6): 73-80. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-HKCB201106014.htm [13] 刘涛, 刘丰华, 蔡长春, 等. 单向纤维增强铝基复合材料轴向剪切损伤与失效行为的细观力学分析[J]. 塑性工程学报, 2022, 29 (7): 171-180. https://www.cnki.com.cn/Article/CJFDTOTAL-SXGC202207023.htmLIU Tao, LIU Fenghua, CAI Changchun, et al. Micromechanics analysis of axial shear damage and failure behavior of unidirectional fiber-reinforced aluminum matrix composites[J]. Journal of Plasticity Engineering, 2022, 29 (7): 171-180. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-SXGC202207023.htm [14] 张永正, 刘磊, 刘琦, 等. C/SiC编织型复合材料热/力学性能的多尺度预测[J]. 应用数学和力学, 2023, 44 (10): 1157-1171. doi: 10.21656/1000-0887.440056 ZHANG Yongzheng, LIU Lei, LIU Qi, et al. Multi-scale prediction of thermal and mechanical properties of C/SiC braided composites[J]. Applied Mathematics and Mechanics, 2023, 44 (10): 1157-1171. (in Chinese) doi: 10.21656/1000-0887.440056 [15] 刘志明, 陈静芬, 毛欢, 等. 基于率相关三维弹塑性损伤模型的复合材料渐进失效分析[J]. 复合材料学报, 2022, 39 (5): 2482-2494. https://www.cnki.com.cn/Article/CJFDTOTAL-FUHE202205055.htmLIU Zhiming, CHEN Jingfen, MAO Huan, et al. Progressive failure analysis of composite materials based on rate-dependent three-dimensional elasto-plastic damage model[J]. Acta Materiae Compositae Sinica, 2022, 39 (5): 2482-2494. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-FUHE202205055.htm [16] 杨凤祥, 陈静芬, 陈善富, 等. 基于剪切非线性三维损伤本构模型的复合材料层合板失效强度预测[J]. 复合材料学报, 2020, 37 (9): 2207-2222. https://www.cnki.com.cn/Article/CJFDTOTAL-FUHE202009013.htmYANG Fengxiang, CHEN Jingfen, CHEN Shanfu, et al. Failure strength prediction of composite laminates using 3D damage constitutive model with nonlinear shear effects[J]. Acta Materiae Compositae Sinica, 2020, 37 (9): 2207-2222. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-FUHE202009013.htm [17] 柳占立, 初东阳, 王涛, 等. 爆炸和冲击载荷下金属材料及结构的动态失效仿真[J]. 应用数学和力学, 2021, 42 (1): 1-14. doi: 10.21656/1000-0887.410262LIU Zhanli, CHU Dongyang, WANG Tao, et al. Dynamic failure simulation of metal materials and structures under blast and impact loading[J]. Applied Mathematics and Mechanics, 2021, 42 (1): 1-14. (in Chinese) doi: 10.21656/1000-0887.410262 [18] LADEVEZE P, LEDANTEC E. Damage modelling of the elementary ply for laminated composites[J]. Composites Science and Technology, 1992, 43 (3): 257-267. [19] 龚煦. 复合材料机翼前缘抗鸟撞分析[D]. 西安: 西北工业大学, 2016.GONG Xu. Numerical analysis of bird strike on an aircraft wing leading edge made from CERP composite[D]. Xi'an: Northwestern Polytechnical University, 2016. (in Chinese) [20] 张安康, 陈士海. LS-DYNA用户自定义材料模型开发与验证[J]. 计算机应用与软件, 2011, 28 (4): 71-73. https://www.cnki.com.cn/Article/CJFDTOTAL-JYRJ201104020.htmZHANG Ankang, CHEN Shihai. Exploiting and verifying user-defined material in LS-DYNA[J]. Computer Applications and Software, 2011, 28 (4): 71-73. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-JYRJ201104020.htm [21] O'HIGGINS R M, MCCARTHY C T, MCCARTHY M A. Identification of damage and plasticity parameters for continuum damage mechanics modelling of carbon and glass fibre-reinforced composite materials[J]. Strain, 2011, 47 (1): 105-115. [22] Standard test method for in-plane shear response of polymer matrix composite materials by tensile test of a ±45° laminate: ASTM D3518/D3518M[M]//Annual Book of ASTM Standards, Vol 15.03. 2001. [23] WANG C, SUO T, HANG C, et al. Influence of in-plane tensile preloads on impact responses of composite laminated plates[J]. International Journal of Mechanical Sciences, 2019, 161/162 : 105012. -

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号