In-Plane Crashworthiness of Graded Hierarchical Hexagonal Honeycombs

edited-by

edited-by

(Contributed by TAO Yong, M.AMM Youth Editorial Board)-

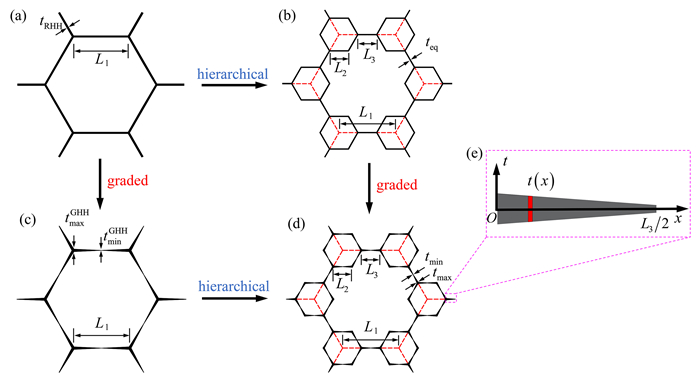

摘要: 梯度设计和多级设计在提高蜂窝材料的力学和吸能性能方面各有优势. 受天然蜂窝的启发,该文基于梯度蜂窝材料和多级蜂窝材料,结合变壁厚梯度设计和节点型多级设计的概念,提出了一种新型梯度多级六边形蜂窝材料. 利用增材制造技术制备了梯度多级六边形蜂窝试件,并通过试验和数值模拟研究了新型梯度多级六边形蜂窝的面内耐撞性,分析对比了梯度设计和多级设计对梯度多级六边形蜂窝面内耐撞性的影响规律. 研究结果表明,结合梯度设计和多级设计可以显著增强蜂窝材料的面内耐撞性,且会出现明显的负Poisson比现象. 此外,相比于多级设计,梯度设计对蜂窝材料的力学和吸能性能的增强效果更加显著.Abstract: Gradient and hierarchical designs have their own advantages in improving the mechanical and energy-absorption properties of honeycombs. Inspired by natural honeycomb, a novel gradient hierarchical hexagonal honeycomb (GHHH) was proposed based on gradient honeycombs and hierarchical honeycombs, to combine the concepts of gradient design with variable wall thicknesses and vertex hierarchical design. The GHHH specimens were fabricated with the additive manufacturing technology. The in-plane crashworthiness of the novel GHHH was investigated through experiments and numerical simulations, and the effects of gradient design and hierarchical design on the in-plane crashworthiness of GHHH were analyzed and compared. The results show that, the combination of gradient design and hierarchical design can significantly increase the in-plane crashworthiness of honeycomb materials, and a significant negative Poisson's ratio phenomenon will occur. In addition, the gradient design is more effective in enhancing the mechanical and energy absorption properties of the honeycomb materials than the hierarchical design.

-

Key words:

- graded hierarchical honeycomb /

- in-plane /

- crashworthiness /

- additive manufacturing

edited-byedited-by1) (我刊青年编委陶勇来稿) -

表 1 GHHH试件的几何参数

Table 1. The detailed parameters of the GHHH specimens

L1 teq λ k ρ 12 mm 0.8 mm 2/3 0.5 0.128 3 -

[1] 田耕鑫, 曹升虎, 张健. 倒刺型接触超材料力学性能研究[J]. 应用数学和力学, 2024, 45(9): 1172-1181. doi: 10.21656/1000-0887.440285TIAN Gengxin, CAO Shenghu, ZHANG Jian. Study on mechanical properties of barbed contact metamaterials[J]. Applied Mathematics and Mechanics, 2024, 45(9): 1172-1181. (in Chinese) doi: 10.21656/1000-0887.440285 [2] 原庆丹, 郭俊宏. 一维纳米准晶层合梁的非局部振动、屈曲与弯曲研究[J]. 应用数学和力学, 2024, 45(2): 208-219. doi: 10.21656/1000-0887.440260YUAN Qingdan, GUO Hongjun. Nonlocal vibration, buckling and bending of 1D layered quasicrystal nanobeams[J]. Applied Mathematics and Mechanics, 2024, 45(2): 208-219. (in Chinese) doi: 10.21656/1000-0887.440260 [3] 王鑫特, 刘娟, 胡彪, 等. 多孔功能梯度压电纳米壳中波传播特性[J]. 应用数学和力学, 2024, 45(2): 197-207. doi: 10.21656/1000-0887.440057WANG Xinte, LIU Juan, HU Biao, et al. Wave propagation characteristics in porous functionally graded piezoelectric nanoshells[J]. Applied Mathematics and Mechanics, 2024, 45(2): 197-207. (in Chinese) doi: 10.21656/1000-0887.440057 [4] MOUSANEZHAD D, BABAEE S, EBRAHIMI H, et al. Hierarchical honeycomb auxetic metamaterials[J]. Scientific Reports, 2015, 5: 18306. doi: 10.1038/srep18306 [5] 王敏学. 分形梯度多孔材料及其夹芯结构抗冲击性能研究[D]. 南京: 东南大学, 2023.WANG Minxue. Study on impact behaviors of hierarchical graded cellular materials and sandwich structures[D]. Nanjing: Southeast University, 2023. (in Chinese) [6] 邓俊杰. 混合型层级蜂窝力学行为及耐撞性研究[D]. 长沙: 中南大学, 2023.DENG Junjie. Research on the mechanical behavior and crashworthiness of the hybrid hierarchical honeycomb[D]. Changsha: Central South University, 2023. (in Chinese) [7] TATLIER M S, MITAT Ö, BARAN T. Linear and non-linear in-plane behaviour of a modified re-entrant core cell[J]. Engineering Structures, 2021, 234: 111984. doi: 10.1016/j.engstruct.2021.111984 [8] QI C, JIANG F, YANG S. Advanced honeycomb designs for improving mechanical properties: a review[J]. Composites (Part B): Engineering, 2021, 227: 109393. doi: 10.1016/j.compositesb.2021.109393 [9] XU F, ZHANG X, ZHANG H. A review on functionally graded structures and materials for energy absorption[J]. Engineering Structures, 2018, 171: 309-325. doi: 10.1016/j.engstruct.2018.05.094 [10] TAO Y, LI W, WEI K, et al. Mechanical properties and energy absorption of 3D printed square hierarchical honeycombs under in-plane axial compression[J]. Composites (Part B): Engineering, 2019, 176: 107219. doi: 10.1016/j.compositesb.2019.107219 [11] QIN R, ZHOU J, CHEN B. Crashworthiness design and multiobjective optimization for hexagon honeycomb structure with functionally graded thickness[J]. Advances in Materials Science and Engineering, 2019, 2019: 8938696. [12] LI Z, JIANG Y, WANG T, et al. In-plane crushing behaviors of piecewise linear graded honeycombs[J]. Composite Structures, 2019, 207: 425-437. doi: 10.1016/j.compstruct.2018.09.036 [13] TAO Y, DUAN S, WEN W, et al. Enhanced out-of-plane crushing strength and energy absorption of in-plane graded honeycombs[J]. Composites (Part B): Engineering, 2017, 118: 33-40. doi: 10.1016/j.compositesb.2017.03.002 [14] YAO R, PANG T, ZHANG B, et al. On the crashworthiness of thin-walled multi-cell structures and materials: state of the art and prospects[J]. Thin-Walled Structures, 2023, 189: 110734. doi: 10.1016/j.tws.2023.110734 [15] WANG Z, LI Z, SHI C, et al. Theoretical and numerical analysis of the folding mechanism of vertex-based hierarchical honeycomb structure[J]. Mechanics of Advanced Materials and Structures, 2020, 27(10): 789-799. doi: 10.1080/15376494.2019.1665760 [16] WANG Z, DENG J, LIU K, et al. Hybrid hierarchical square honeycomb with widely tailorable effective in-plane elastic modulus[J]. Thin-Walled Structures, 2022, 171: 108816. doi: 10.1016/j.tws.2021.108816 [17] WANG Z, DENG J, HE K, et al. Out-of-plane crushing behavior of hybrid hierarchical square honeycombs[J]. Thin-Walled Structures, 2022, 181: 110051. doi: 10.1016/j.tws.2022.110051 [18] AJDARI A, JAHROMI B H, PAPADOPOULOS J, et al. Hierarchical honeycombs with tailorable properties[J]. International Journal of Solids and Structures, 2012, 49(11/12): 1413-1419. [19] CHEN Y, LI T, JIA Z, et al. 3D printed hierarchical honeycombs with shape integrity under large compressive deformations[J]. Materials & Design, 2018, 137: 226-234. [20] CHEN Y, JIA Z, WANG L. Hierarchical honeycomb lattice metamaterials with improved thermal resistance and mechanical properties[J]. Composite Structures, 2016, 152: 395-402. doi: 10.1016/j.compstruct.2016.05.048 [21] WEN W, LEI M, TAO Y. The effect of material distribution on the out-of-plane elastic properties of hierarchical diamond honeycombs[J]. Engineering Structures, 2022, 272: 115000. doi: 10.1016/j.engstruct.2022.115000 [22] LIU H, ZHANG E T, NG B F. In-plane dynamic crushing of a novel honeycomb with functionally graded fractal self-similarity[J]. Composite Structures, 2021, 270: 114106. doi: 10.1016/j.compstruct.2021.114106 [23] WEN W, LEI M, TAO Y, et al. Out-of-plane crashworthiness of bio-inspired hierarchical diamond honeycombs with variable cell wall thickness[J]. Thin-Walled Structures, 2022, 176: 109347. doi: 10.1016/j.tws.2022.109347 [24] TAYLOR C M, SMITH C W, MILLER W, et al. Functional grading in hierarchical honeycombs: density specific elastic performance[J]. Composite Structures, 2012, 94(8): 2296-2305. doi: 10.1016/j.compstruct.2012.01.021 [25] GIBSON L, ASHBY M. Cellular Solids Structure and Properties[M]. Cambridge: Press Syndicate of the University of Cambridge, 1997. [26] TAO Y, LI W, CHENG T, et al. Out-of-plane dynamic crushing behavior of joint-based hierarchical honeycombs[J]. Journal of Sandwich Structures & Materials, 2021, 23(7): 2832-2855. [27] HE Q, FENG J, ZHOU H. A numerical study on the in-plane dynamic crushing of self-similar hierarchical honeycombs[J]. Mechanics of Materials, 2019, 138: 103151. doi: 10.1016/j.mechmat.2019.103151 [28] WU Y, SUN L, YANG P, et al. Energy absorption of additively manufactured functionally bi-graded thickness honeycombs subjected to axial loads[J]. Thin-Walled Structures, 2021, 164: 107810. doi: 10.1016/j.tws.2021.107810 [29] TAN H L, HE Z C, LI E, et al. Energy absorption characteristics of three-layered sandwich panels with graded re-entrant hierarchical honeycombs cores[J]. Aerospace Science and Technology, 2020, 106: 106073. doi: 10.1016/j.ast.2020.106073 [30] ISAAC C W, DUDDECK F. Recent progress in 4D printed energy-absorbing metamaterials and structures[J]. Virtual and Physical Prototyping, 2023, 18: e2197436. doi: 10.1080/17452759.2023.2197436 [31] ISAAC C W, SOKOŁOWSKI A, DUDDECK F, et al. Mechanical characterisation and crashworthiness performance of additively manufactured polymer-based honeycomb structures under in-plane quasi-static loading[J]. Virtual and Physical Prototyping, 2023, 18: e2273296. doi: 10.1080/17452759.2023.2273296 [32] FENG G, LI S, XIAO L, et al. Energy absorption performance of honeycombs with curved cell walls under quasi-static compression[J]. International Journal of Mechanical Sciences, 2021, 210: 106746. doi: 10.1016/j.ijmecsci.2021.106746 [33] LI S, LIU Z, SHIM V P W, et al. In-plane compression of 3D-printed self-similar hierarchical honeycombs: static and dynamic analysis[J]. Thin-Walled Structures, 2020, 157: 106990. doi: 10.1016/j.tws.2020.106990 [34] HA N S, PHAM T M, CHEN W, et al. Crashworthiness analysis of bio-inspired fractal tree-like multi-cell circular tubes under axial crushing[J]. Thin-Walled Structures, 2021, 169: 108315. doi: 10.1016/j.tws.2021.108315 [35] LIU H, ZHANG E T, WANG G, et al. In-plane crushing behavior and energy absorption of a novel graded honeycomb from hierarchical architecture[J]. International Journal of Mechanical Sciences, 2022, 221: 107202. doi: 10.1016/j.ijmecsci.2022.107202 -

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号